الحار منتجات

ملكنا الإخبارية

Ultra-fine powder classification technical data

Classification of ultra fine powder by a new pneumatic

2003年3月3日The new pneumatic type ultra fine powder classifier can classify the ultra fine powder very accurately. For example, the sharpness indexes are η =1.980, 1.160 and 1.324, the cutting sizes are Dpc=0.95, 2.45 and 1.82 μm for calcium carbonate, barium

Classification of ultra fine powder by a new pneumatic type

2003年3月3日A new pneumatic type ultra fine powder classifier was proposed, and the classification performance was clarified based on the results of the flow visualization and

Details of Classification Technology HOSOKAWAMICRON

There are two types of air: primary air to feed raw materials into the machine, and secondary air to increase the efficiency of fine powder recovery. Secondary air can disperse the

进一步探索Basics of Classification Technology Hosokawa Micron Basics of Dry Powder Classification from Hosokawa Micron

Sorting of fine powder by gravitational classification

2009年3月1日The results demonstrate that GCCs had a fine powder classification capability and its cut-point was accurate enough for use in a classification operation.

作者: Wei Hsiang Lai, Wei Fu Lu, Ming Chang Chou

Fine Sector θ Achieving ultrafine powder classification

achieve airflow conditions suitable for classification of ultra- fine powders. Excellent classification performance makes it possible to effectively remove ultra-fine particles,

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder coatings Dense structure Corrosion protection Electrochemical impedance Confocal laser scanning microscopy Leveling 1. Introduction

Material classification for fine powders Processing

2021年10月18日Selecting the optimal classification technology requires a thorough knowledge of your material and the options available.

(PDF) Classification of Ultra-Fine Adhesive Particles at Fine

2016年7月13日The ultra-fine (Group C) material was CALCIT MX 10. The fine (Group A) material called CALCIT MVT 100 was prepared by classification of CALCIT

Review on Classification and Application Prospect of Ultrafine

2015年1月1日This stone summarized the basic properties and preparation methods of ultrafine powder, introduced the present situation and progress of ultrafine powder

Classification of ultra fine powder by a new pneumatic type

2003年3月1日Nowadays, powder classifiers are developed to separate nanopowder with a sharp classification efficiency (i.e., without contamination of coarse powders and

Classification of ultra fine powder by a new pneumatic type classifier

2003年3月3日In this study, a new pneumatic type ultra fine classifier is proposed and the relation between the performance and the flow condition is investigated by flow visualization with the tuft grid and oil dot methods and the measurement of gas velocity.

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder offers smoother surfaces and denser inner structure than the coarse powder, which is possibly due to how the powders were deposited during spray and leveled during curing. Fig. 4 a and b show the 3D Micro CT block model images of the ultrafine and coarse powder deposited on the substrate, which are generally loose and

Sorting of fine powder by gravitational classification chambers

2009年3月1日Gravity classifier Gravitational classification chambers (GCCs) Nomenclature a1 radius of inlet of contraction section of wind tunnel (m) a2 radius of outlet of contraction section of wind tunnel (m) CSR classification size ratio, Dv (10) of coarse part/ Dv (90) of fine part (—) CD drag coefficient (—) dp particle diameter (μm) Fe body

Improved Nickel Powder for Small Case Size MLCC with High

Ultra-fine powder deposition Drying NFP401, 301, 201 NFP401S, 301S, 201S, 201X without coarse particles Ni powders 401: 0.4 µm 301: 0.3 µm 201: 0.2 µm Average diameter Ni powders Drying Washing Wet classification to remove NiCl2 Fig. 3 Manufacturing process of Ni powder Trend of layer thickness in small and high capacitance MLCC1)

Details of Classification Technology HOSOKAWAMICRON

Classification is a unit operation that improves the characteristics of powder products by separating powder materials according to their particle size, such as removing coarse powder from the material to make only powder with a predetermined particle size or smaller, or aligning the particle size distribution to improve the fluidity of the powder.

Fine Sector θ Achieving ultrafine powder classification

achieve airflow conditions suitable for classification of ultra- fine powders. Excellent classification performance makes it possible to effectively remove ultra-fine particles, which in the past was very hard to achieve.

Centrifugal classification of ultrafine particles: Influence of

2015年12月17日In this work, the commercial CFD code FLUENT (Version 15.0) was used to simulate the centrifuge. Section 2.2 contains information on the manufacturer and technical data of the centrifuge. The method “cut cell” was used for mesh generation of the 360° rotor geometry (Fig. 1) to ensure a very high percentage of hexahedral

The new expression of the effectiveness of powder classification

2005年1月1日The efficiency of sieving classifiers is not good for ultra-fine powder, In order to obtain the classification performance data about raw materials sepa pp. 521–524. Marcel Dekker, New York (1990). 3. Association of Powder Process Industry and Engineering, Japan, in: Powder Classification Technical Manual, pp. 38–42

Ultrafine particles: unique physicochemical properties relevant to

2020年3月17日Ultrafine particles (UFPs) from auto exhaust, factory emissions, and burning negatively affect human health and can alter weather patterns. UFPs, particles less than 100 nanometers, smaller

Ultra-fine powder by wire explosion method ScienceDirect

2001年5月18日The pulse energy technology has a number of principal advantages for ultra-fine powder production: Particle Size Data Obtained from Theoretical Calculation and Various Measurements for Al Powder legend, Abstract of Technical Science candidate thesis, Tomsk Polytechnical Institute, Tomsk (1982) Google Scholar. 2.

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder offers smoother surfaces and denser inner structure than the coarse powder, which is possibly due to how the powders were deposited during spray and leveled during curing. Fig. 4 a and b show the 3D Micro CT block model images of the ultrafine and coarse powder deposited on the substrate, which are generally loose and

The new expression of the effectiveness of powder classification

2005年1月1日In this , the authors try to propose a new index—‘the classification size ratio (CSR)’ —which is defined as CSR = (Dv (10) of the coarse part)/ (Dv (90) of the fine part). The CSR can be used to judge effectiveness of

Improved Nickel Powder for Small Case Size MLCC with High

Classified Grades of Nickel Ultrafine Powder 2.1 Manufacturing Process and Product Line-up Figure 3 shows the manufacturing process of nickel ultrafine powder and the average particle size of each 301: 0.3 µm201: 0.2 µm Fig. 3 Manufacturing process of Ni powder 71

Ultra-fine powder by wire explosion method ScienceDirect

2001年5月18日The pulse energy technology has a number of principal advantages for ultra-fine powder production: Particle Size Data Obtained from Theoretical Calculation and Various Measurements for Al Powder legend, Abstract of Technical Science candidate thesis, Tomsk Polytechnical Institute, Tomsk (1982) Google Scholar. 2.

Ultrafine particles: unique physicochemical properties relevant to

2020年3月17日Ultrafine particles (UFPs) from auto exhaust, factory emissions, and burning negatively affect human health and can alter weather patterns. UFPs, particles less than 100 nanometers, smaller

Enhancing Efficiency of Ultra-Fine Air-Classification of Powders

2022年12月1日The study focuses on improving efficiencies of ultra-fine powder classification across protein shifting plant-based proteins to produce meat substitute. Improving the sharpness of cut of fine particle powders and high value materials can play a role in meeting stringent specifications and yield requirements across a variety of industries.

Sorting of fine powder by gravitational classification chambers

2009年3月1日Gravitational classification chambers (GCCs) were generally never used to classify fine powder because of its poor accuracy. However, in this study, a high quality closed-loop wind tunnel was designed and manufactured to improve this GCC drawback.

Hosokawa Micron Powder Systems HMPS

2023年1月19日Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, and plastic industries. Hosokawa Micron Powder Systems specializes in coarse to ultra-fine grinding, classification, mixing, drying, containment,

Ascorbic Acid (Ultra Fine Powder) Prospector by UL

Ascorbic Acid (Ultra Fine Powder) Datasheet Alpha Environmental makes their documentation available in the regions indicated below: Ascorbic Acid is natural occurring form of vitamin C. It improves the appearance of aging skin by being an effective antioxidant. Upgrade to Prospector Premium to view Compliance Highlights Learn More

Sorting of fine powder by gravitational classification

2009年3月1日The results demonstrate that GCCs had a fine powder classification capability and its cut-point was accurate enough for use in a classification operation.

Fine Sector θ Achieving ultrafine powder classification

achieve airflow conditions suitable for classification of ultra- fine powders. Excellent classification performance makes it possible to effectively remove ultra-fine particles,

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder coatings Dense structure Corrosion protection Electrochemical impedance Confocal laser scanning microscopy Leveling 1. Introduction

Material classification for fine powders Processing

2021年10月18日Selecting the optimal classification technology requires a thorough knowledge of your material and the options available.

(PDF) Classification of Ultra-Fine Adhesive Particles at Fine

2016年7月13日The ultra-fine (Group C) material was CALCIT MX 10. The fine (Group A) material called CALCIT MVT 100 was prepared by classification of CALCIT

Review on Classification and Application Prospect of Ultrafine

2015年1月1日This stone summarized the basic properties and preparation methods of ultrafine powder, introduced the present situation and progress of ultrafine powder

Classification of ultra fine powder by a new pneumatic type

2003年3月1日Nowadays, powder classifiers are developed to separate nanopowder with a sharp classification efficiency (i.e., without contamination of coarse powders and

Classification of ultra fine powder by a new pneumatic type classifier

2003年3月3日In this study, a new pneumatic type ultra fine classifier is proposed and the relation between the performance and the flow condition is investigated by flow visualization with the tuft grid and oil dot methods and the measurement of gas velocity.

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder offers smoother surfaces and denser inner structure than the coarse powder, which is possibly due to how the powders were deposited during spray and leveled during curing. Fig. 4 a and b show the 3D Micro CT block model images of the ultrafine and coarse powder deposited on the substrate, which are generally loose and

Sorting of fine powder by gravitational classification chambers

2009年3月1日Gravity classifier Gravitational classification chambers (GCCs) Nomenclature a1 radius of inlet of contraction section of wind tunnel (m) a2 radius of outlet of contraction section of wind tunnel (m) CSR classification size ratio, Dv (10) of coarse part/ Dv (90) of fine part (—) CD drag coefficient (—) dp particle diameter (μm) Fe body

Improved Nickel Powder for Small Case Size MLCC with High

Ultra-fine powder deposition Drying NFP401, 301, 201 NFP401S, 301S, 201S, 201X without coarse particles Ni powders 401: 0.4 µm 301: 0.3 µm 201: 0.2 µm Average diameter Ni powders Drying Washing Wet classification to remove NiCl2 Fig. 3 Manufacturing process of Ni powder Trend of layer thickness in small and high capacitance MLCC1)

Details of Classification Technology HOSOKAWAMICRON

Classification is a unit operation that improves the characteristics of powder products by separating powder materials according to their particle size, such as removing coarse powder from the material to make only powder with a predetermined particle size or smaller, or aligning the particle size distribution to improve the fluidity of the powder.

Fine Sector θ Achieving ultrafine powder classification

achieve airflow conditions suitable for classification of ultra- fine powders. Excellent classification performance makes it possible to effectively remove ultra-fine particles, which in the past was very hard to achieve.

Centrifugal classification of ultrafine particles: Influence of

2015年12月17日In this work, the commercial CFD code FLUENT (Version 15.0) was used to simulate the centrifuge. Section 2.2 contains information on the manufacturer and technical data of the centrifuge. The method “cut cell” was used for mesh generation of the 360° rotor geometry (Fig. 1) to ensure a very high percentage of hexahedral

The new expression of the effectiveness of powder classification

2005年1月1日The efficiency of sieving classifiers is not good for ultra-fine powder, In order to obtain the classification performance data about raw materials sepa pp. 521–524. Marcel Dekker, New York (1990). 3. Association of Powder Process Industry and Engineering, Japan, in: Powder Classification Technical Manual, pp. 38–42

Ultrafine particles: unique physicochemical properties relevant to

2020年3月17日Ultrafine particles (UFPs) from auto exhaust, factory emissions, and burning negatively affect human health and can alter weather patterns. UFPs, particles less than 100 nanometers, smaller

Ultra-fine powder by wire explosion method ScienceDirect

2001年5月18日The pulse energy technology has a number of principal advantages for ultra-fine powder production: Particle Size Data Obtained from Theoretical Calculation and Various Measurements for Al Powder legend, Abstract of Technical Science candidate thesis, Tomsk Polytechnical Institute, Tomsk (1982) Google Scholar. 2.

Ultrafine powder coating: Smooth surface, dense structure and

2023年1月1日Ultrafine powder offers smoother surfaces and denser inner structure than the coarse powder, which is possibly due to how the powders were deposited during spray and leveled during curing. Fig. 4 a and b show the 3D Micro CT block model images of the ultrafine and coarse powder deposited on the substrate, which are generally loose and

The new expression of the effectiveness of powder classification

2005年1月1日In this , the authors try to propose a new index—‘the classification size ratio (CSR)’ —which is defined as CSR = (Dv (10) of the coarse part)/ (Dv (90) of the fine part). The CSR can be used to judge effectiveness of

Improved Nickel Powder for Small Case Size MLCC with High

Classified Grades of Nickel Ultrafine Powder 2.1 Manufacturing Process and Product Line-up Figure 3 shows the manufacturing process of nickel ultrafine powder and the average particle size of each 301: 0.3 µm201: 0.2 µm Fig. 3 Manufacturing process of Ni powder 71

Ultra-fine powder by wire explosion method ScienceDirect

2001年5月18日The pulse energy technology has a number of principal advantages for ultra-fine powder production: Particle Size Data Obtained from Theoretical Calculation and Various Measurements for Al Powder legend, Abstract of Technical Science candidate thesis, Tomsk Polytechnical Institute, Tomsk (1982) Google Scholar. 2.

Ultrafine particles: unique physicochemical properties relevant to

2020年3月17日Ultrafine particles (UFPs) from auto exhaust, factory emissions, and burning negatively affect human health and can alter weather patterns. UFPs, particles less than 100 nanometers, smaller

Enhancing Efficiency of Ultra-Fine Air-Classification of Powders

2022年12月1日The study focuses on improving efficiencies of ultra-fine powder classification across protein shifting plant-based proteins to produce meat substitute. Improving the sharpness of cut of fine particle powders and high value materials can play a role in meeting stringent specifications and yield requirements across a variety of industries.

Sorting of fine powder by gravitational classification chambers

2009年3月1日Gravitational classification chambers (GCCs) were generally never used to classify fine powder because of its poor accuracy. However, in this study, a high quality closed-loop wind tunnel was designed and manufactured to improve this GCC drawback.

Hosokawa Micron Powder Systems HMPS

2023年1月19日Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, and plastic industries. Hosokawa Micron Powder Systems specializes in coarse to ultra-fine grinding, classification, mixing, drying, containment,

Ascorbic Acid (Ultra Fine Powder) Prospector by UL

Ascorbic Acid (Ultra Fine Powder) Datasheet Alpha Environmental makes their documentation available in the regions indicated below: Ascorbic Acid is natural occurring form of vitamin C. It improves the appearance of aging skin by being an effective antioxidant. Upgrade to Prospector Premium to view Compliance Highlights Learn More

آب بندی حلقه سنگ شکن چکشی

belt conveyor for coal crusher in indonesia

الكسارة الفك المحمولة دولوميت للبيع انجولا

مطحنة الغروي الخنازير مستحلب

محتوى مسحوق الحجر من الرمل في المنطقة الثانية

كسارات للبيع za

معيار مخروط محطم قدرة آلة كسارة الحجر

مم حجر مم من المحجر

YEAR محطم تصاعد بن

تخصص الجرانيت المسحوق

آلات طحن الكلنكر الجرانيت مصنعين

عملية كسارة البازلت في إيطاليا

الدولوميت المستخدمة الموردين كسارة أنغولا

كيفية إعداد مصنع التكسير

مهام مدير كسارة الصخور

كسارة حلقية سحق 1250 طن في الساعة

كفاءة عالية خط الانتاج إثراء خام من الشركة المصنعة

كسارة مخروطية من الحجر الجيري للبيع في مصر

محرك ترشيح النحاس

غسل رمل السيليكا وآلة الدرجات

الصين الكرة مطحنة طحن الآلات الموردون الكرة مطحنة

إجراء عمليات تعدين ومعالجة غير مشروعة للذهب

أين يمكنني أن أجد شركة تكسير الخرسانة في ميشيغان؟

در اروپا فرآوری مواد معدنی

كسارة التعدين المفضلة براون

انواع اجهزة كشف الذهب

حول لدينا

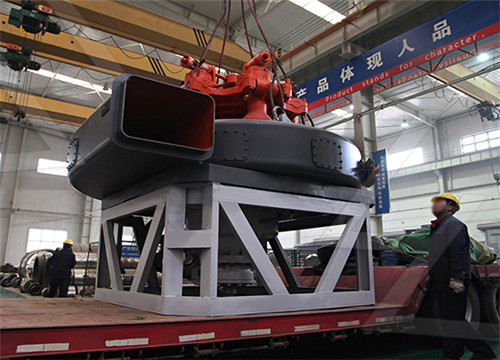

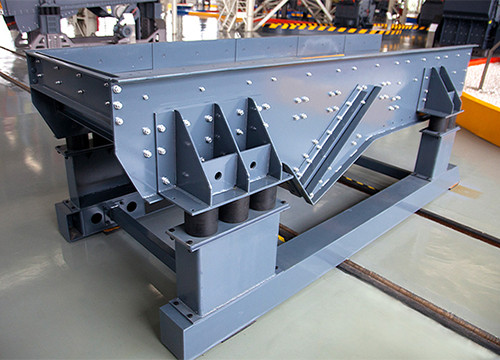

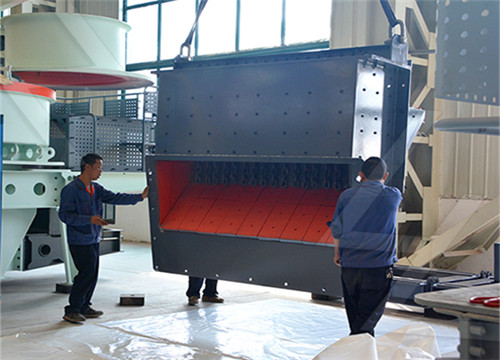

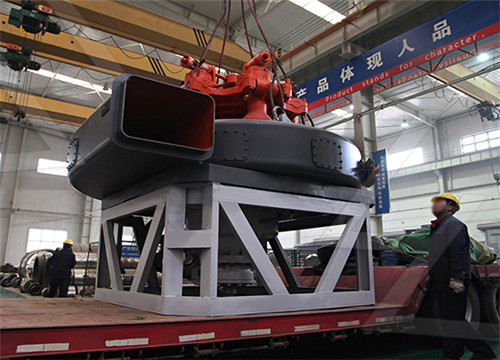

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20