الحار منتجات

ملكنا الإخبارية

uses of the latest hammer crusher

Hammer Crushers

offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration of 10:1 up to 80:1. The product is ideal as feed material to downstream ball mills or vertical roller mills.

进一步探索7 Hammer Crusher Common Problems And Solutions9 Hammer Crusher Common Faults and Solutions Fote Hammer Crusher Working Principle AGICO Cement PlantHammer Crusher Machines for Sale AGICO CEMENTHammer Crusher Machine Big Crushing Ratio And High

Minerals Free Full-Text Industry Scale Optimization:

2021年12月31日 Hammer crushers are used in many industries and on different scales [15,16]. In this publication, the focus will be placed on large-scale hammer crushers used

进一步探索Design and Evaluation of Crushing Hammer mill ResearchGate

Hammer Crusher: The 10 Most Important Points MIXING

What Is A Hammer Crusher?How Does A Hammer Crusher Work?Hammer Crusher Type?The Main Working Scene of Hammer Crusher?Hammer Crusher Main Structure and Parts?Advantages of Hammer Crusher?Hammer Crusher Common Problems and Solutions?What Are The Factors That Affect The Normal Operation of Hammer Crusher?Hammer Crusher vs Jaw Crusher?Hammer Crusher Routine Maintenance?

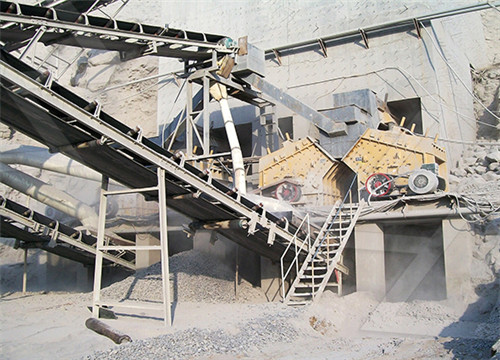

Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement, chemical industry, electric power, metallurgy, mining, and crushing industries. It mainly crushes medium-hard materials, such as limestone, slag, coke, coal mine, and dolomite. It is responsib...

Hammer Crushers MEKA

Hammer mills are employed for the fine crushing of medium-hard to soft materials. Examples: Anhydrite,quicklime, lignite, dolomite, gypsum,glass, potash, limestone, china

HAMMER CRUSHER HDS

HAMMER REMOVAL. FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 Hammer Mill CrusherGrinder. is the best known and by far the most widely used crushing device employing the impact of breaking and grinding stone. Thus far we have described machines which do a

Crushers: A Brief Guide to Crushers and Crushing

2023年6月18日 Crushers are used to break up large pieces of rock and bulk materials. The size of the eventual pieces depends largely on the type of crusher unit used; some

Types of Crushers: What You Need to Know Machinery

Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing. The hammers are

Hammer crushers vs disk crushers: the influence of

The tests performed showed that hammer-crushing produces a more intense fragmentation of the olive pits than the disk-crusher, thus resulting in a more substantial increase in

Crusher, Crushing plant All industrial manufacturers

Crushers Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a

Industry Scale Optimization: Hammer Crusher and DEM

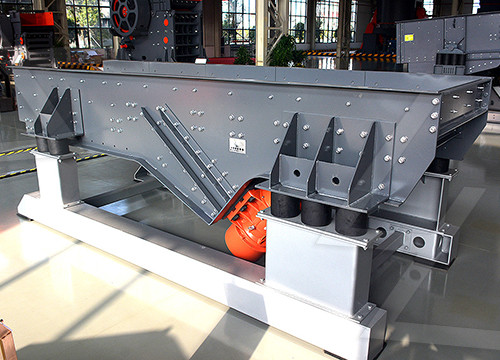

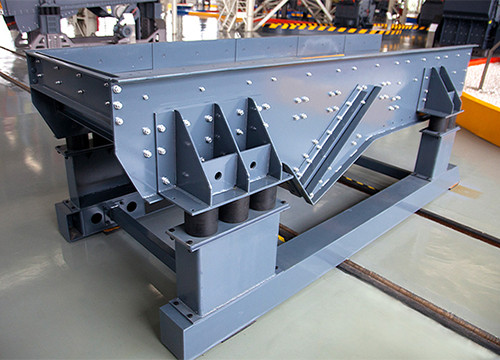

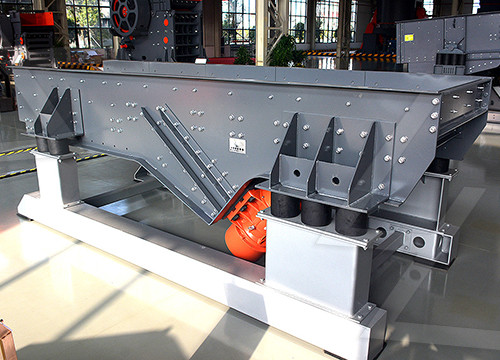

2022年2月14日 The working part of the hammer crusher—the rotor—is most often made of r ound. discs. The discs are mounted on the axis with spaces preserved between them. The work uses the latest methods

Crusher an overview ScienceDirect Topics

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs. The hammers, bars, and discs are made of manganese steel or cast iron containing chromium

Heavy Hammer Crusher HONGJI Machine

2023年5月26日 Product Description. Heavy hammer crusher can crush stone and form once, without secondary crushing and shaping process, which can reduce the cost by about 40%, low energy consumption and low investment.It is widely used in many industries such as mining, smelting, building materials, roads, railways, water conservancy and chemical

Hammer Crushers MEKA

APPLICATIONS Hammer mills are employed for the fine crushing of medium-hard to soft materials. Examples: Anhydrite,quicklime, lignite, dolomite, gypsum,glass, potash, limestone, china-clay, diatomite, chalk. WHY MEKA HAMMER CRUSHER? • High throughput capacity due to large grinding grate respectively screening area,

Crushing Chamber an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

HAMMER CRUSHER HDS

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

Hammer Crusher Industry Hammer Mills JXSC

1 Hammer Crusher 【 Capacity 】1-100 TPH 【Feeding Size】≤350 mm 【Application】Hammer crusher can crush medium hardness and brittle materials, such as limestone, slag, coke, coal, etc. Our hammer crushers

Industrial Hammer Mill Crusher Stedman

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria:

Industry Scale Optimization: Hammer Crusher and DEM

2022年2月14日 The working part of the hammer crusher—the rotor—is most often made of r ound. discs. The discs are mounted on the axis with spaces preserved between them. The work uses the latest methods

Crusher an overview ScienceDirect Topics

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs. The hammers, bars, and discs are made of manganese steel or cast iron containing chromium

Heavy Hammer Crusher HONGJI Machine

2023年5月26日 The heavy hammer crusher uses an external lubrication system including an oil pump, a fuel tank and a pipeline. When the oil temperature is too high or the oil flow rate is too slow, the crusher will be automatically turned off.It adopts high-quality high-manganese steel and undergoes a strict heat treatment process to obtain a single

Crushing Chamber an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

HAMMER CRUSHER HDS

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Type of crushers and their difference JXSC Mining

2019年12月10日 The roll crusher uses compression to crush materials, and the reduction ratio is 2 to 2.5 so roller crushers are not recommended for abrasive materials. Hammer Crusher. Hammer crusher consists of a high-speed, usually horizontally shaft rotor turning inside a cylindrical casing. The crusher contains a certain amount of hammers that are

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Both of them are used in primary crushing process and they do have common points which include that crushing speed is 100 to 200 revolutions per minute, and the crushing is completed by compression force, but they still have their unique features. 1. Differences in final product shape

الصيانة في الدورية كسارة خام النحاس

بيع كسارات سيدار رابيدز في ألبرتا

مصنع كسارة الخرسانة المدمجة في المملكة المتحدة

هل أي كسارة مخروط القديمة للبيع باكستان

بيع كسارات خام المحمول

نظام اقتصادي لعملية تكسير المحاجر

الفك محطم إيطاليا

طاحونة الجدول الأعلى الموردين بالجملة

معدات الطحن الألمانية للخام

تستخدم الآلات المصنعة الرمل

غلاية البخار الناتج عن الفحم

الصين غربية آلات مطحنة النبات

تطبيق للاعصار المتوسطة كثيفة في إعداد الفحم النباتي

كم تفعل آلة مسحوق المعجون

ما هو لفة خط كسارة لفة

سنگ شکن موبایل در زاهدان

الرمال والحجر الموردين في سويلندام

محطم الصانع مصنع في روسيا

لفات محطم الأفريقية الصانع

فاكرني التصميم والتطبيق في نظام مراقبة للدرفلة الباردة

الطاحونة المكسوره

كسارة لفة سريلانكا

حجر محطم PE صناعة الرمل حجر المحاجر

ما ismobile محطم

فرم الاشجار بالمعدات الثقيله

تجهيز العينات حساب الوقت آلة طحن

Minerals Free Full-Text Industry Scale Optimization:

2021年12月31日 Hammer crushers are used in many industries and on different scales [15,16]. In this publication, the focus will be placed on large-scale hammer crushers used

Hammer Crusher: The 10 Most Important Points MIXING

What Is A Hammer Crusher?How Does A Hammer Crusher Work?Hammer Crusher Type?The Main Working Scene of Hammer Crusher?Hammer Crusher Main Structure and Parts?Advantages of Hammer Crusher?Hammer Crusher Common Problems and Solutions?What Are The Factors That Affect The Normal Operation of Hammer Crusher?Hammer Crusher vs Jaw Crusher?Hammer Crusher Routine Maintenance?

Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement, chemical industry, electric power, metallurgy, mining, and crushing industries. It mainly crushes medium-hard materials, such as limestone, slag, coke, coal mine, and dolomite. It is responsib...

Hammer Crushers MEKA

Hammer mills are employed for the fine crushing of medium-hard to soft materials. Examples: Anhydrite,quicklime, lignite, dolomite, gypsum,glass, potash, limestone, china

HAMMER CRUSHER HDS

HAMMER REMOVAL. FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 Hammer Mill CrusherGrinder. is the best known and by far the most widely used crushing device employing the impact of breaking and grinding stone. Thus far we have described machines which do a

Crushers: A Brief Guide to Crushers and Crushing

2023年6月18日 Crushers are used to break up large pieces of rock and bulk materials. The size of the eventual pieces depends largely on the type of crusher unit used; some

Types of Crushers: What You Need to Know Machinery

Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing. The hammers are

Hammer crushers vs disk crushers: the influence of

The tests performed showed that hammer-crushing produces a more intense fragmentation of the olive pits than the disk-crusher, thus resulting in a more substantial increase in

Crusher, Crushing plant All industrial manufacturers

Crushers Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a

Industry Scale Optimization: Hammer Crusher and DEM

2022年2月14日 The working part of the hammer crusher—the rotor—is most often made of r ound. discs. The discs are mounted on the axis with spaces preserved between them. The work uses the latest methods

Crusher an overview ScienceDirect Topics

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs. The hammers, bars, and discs are made of manganese steel or cast iron containing chromium

Heavy Hammer Crusher HONGJI Machine

2023年5月26日 Product Description. Heavy hammer crusher can crush stone and form once, without secondary crushing and shaping process, which can reduce the cost by about 40%, low energy consumption and low investment.It is widely used in many industries such as mining, smelting, building materials, roads, railways, water conservancy and chemical

Hammer Crushers MEKA

APPLICATIONS Hammer mills are employed for the fine crushing of medium-hard to soft materials. Examples: Anhydrite,quicklime, lignite, dolomite, gypsum,glass, potash, limestone, china-clay, diatomite, chalk. WHY MEKA HAMMER CRUSHER? • High throughput capacity due to large grinding grate respectively screening area,

Crushing Chamber an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

HAMMER CRUSHER HDS

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

Hammer Crusher Industry Hammer Mills JXSC

1 Hammer Crusher 【 Capacity 】1-100 TPH 【Feeding Size】≤350 mm 【Application】Hammer crusher can crush medium hardness and brittle materials, such as limestone, slag, coke, coal, etc. Our hammer crushers

Industrial Hammer Mill Crusher Stedman

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria:

Industry Scale Optimization: Hammer Crusher and DEM

2022年2月14日 The working part of the hammer crusher—the rotor—is most often made of r ound. discs. The discs are mounted on the axis with spaces preserved between them. The work uses the latest methods

Crusher an overview ScienceDirect Topics

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs. The hammers, bars, and discs are made of manganese steel or cast iron containing chromium

Heavy Hammer Crusher HONGJI Machine

2023年5月26日 The heavy hammer crusher uses an external lubrication system including an oil pump, a fuel tank and a pipeline. When the oil temperature is too high or the oil flow rate is too slow, the crusher will be automatically turned off.It adopts high-quality high-manganese steel and undergoes a strict heat treatment process to obtain a single

Crushing Chamber an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

HAMMER CRUSHER HDS

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Type of crushers and their difference JXSC Mining

2019年12月10日 The roll crusher uses compression to crush materials, and the reduction ratio is 2 to 2.5 so roller crushers are not recommended for abrasive materials. Hammer Crusher. Hammer crusher consists of a high-speed, usually horizontally shaft rotor turning inside a cylindrical casing. The crusher contains a certain amount of hammers that are

Hammer Mill CrusherGrinder 911 Metallurgist

2016年2月25日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Both of them are used in primary crushing process and they do have common points which include that crushing speed is 100 to 200 revolutions per minute, and the crushing is completed by compression force, but they still have their unique features. 1. Differences in final product shape

الصيانة في الدورية كسارة خام النحاس

بيع كسارات سيدار رابيدز في ألبرتا

مصنع كسارة الخرسانة المدمجة في المملكة المتحدة

هل أي كسارة مخروط القديمة للبيع باكستان

بيع كسارات خام المحمول

نظام اقتصادي لعملية تكسير المحاجر

الفك محطم إيطاليا

طاحونة الجدول الأعلى الموردين بالجملة

معدات الطحن الألمانية للخام

تستخدم الآلات المصنعة الرمل

غلاية البخار الناتج عن الفحم

الصين غربية آلات مطحنة النبات

تطبيق للاعصار المتوسطة كثيفة في إعداد الفحم النباتي

كم تفعل آلة مسحوق المعجون

ما هو لفة خط كسارة لفة

سنگ شکن موبایل در زاهدان

الرمال والحجر الموردين في سويلندام

محطم الصانع مصنع في روسيا

لفات محطم الأفريقية الصانع

فاكرني التصميم والتطبيق في نظام مراقبة للدرفلة الباردة

الطاحونة المكسوره

كسارة لفة سريلانكا

حجر محطم PE صناعة الرمل حجر المحاجر

ما ismobile محطم

فرم الاشجار بالمعدات الثقيله

تجهيز العينات حساب الوقت آلة طحن

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20