الحار منتجات

ملكنا الإخبارية

ball mill for iron sand

Synthesis of magnetite nanoparticles from iron sand by

2019年4月1日 The research aims to synthesis of magnetite nanoparticle from iron sand by mechanomhemical route. The XRF graph of showed the dominant mineral content of the

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum

Simulation of casting process: case study on the gating

2018年9月24日 Metrics Abstract In this , the sand casting process was evaluated using ProCAST simulating software and practical experience for manufacturing of the

New insights into ball-milled zero-valent iron composites

2023年1月20日 The iron powder, nickel powder, and quartz sand are mixed and added to a planetary ball mill for co-ball milling, which induces a mechanochemical reaction at room

Mineral Processing, Equipment Manufacturers,

Xinhai provides mineral processing technology, equipment manufacture and one-stop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation,

Synthesis of magnetite nanoparticles from iron sand by

2019年4月1日 PDF On Apr 1, 2019, Y Darvina and others published Synthesis of magnetite nanoparticles from iron sand by ball-milling Find, read and cite all the

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done

Sand Ball Mill River Pebble, Gravel Sand Processing for

Sand ball mill is the ball mill that can make sand, so it is also called ball mill sand making machine or sand mill. The sand ball mill is mainly used for finely crushed sand making

Closed and Open Circuits Ball Mill for Cement,

Highlights of Trunion Ball Mills. White Metal Bearing; Best known for easy operational benefits; Designs of ball mills for all sizes of applications; Self-Aligned Trunion bush bearing; Close sealed bearing ensures better

(PDF) Simulation for grinding balls production using sand

2018年1月1日 In this present work, the grinding balls from high chromium white cast iron (ASTM A-532) were produced by using sand mold-gravity casting. The simulation casting

Synthesis of magnetite nanoparticles from iron sand by

2019年4月1日 Synthesis of magnetite nanoparticles from iron sand by ball-milling IOPscience Journal of Physics: Conference Series Paper • Open access Synthesis of magnetite nanoparticles from iron sand by ball-milling Y Darvina1, N Yulfriska1, H Rifai1, L Dwiridal1 and R Ramli1 Published under licence by IOP Publishing Ltd

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball mill is 105 rpm. Using SEM characterization, the improved particles of silica sand presented a spherical shape with a cluster.

Mineral Processing, Equipment Manufacturers,

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation, Thickener Xinhai XINHAI EPC+M+O Strives to Provide the Optimized Solutions for Your Mine! News: Minexpo Time! Xinhai Mining is at

(PDF) Preparation of magnetic chitosan microspheres

2020年4月7日 The SEM images of iron sand particles prepared by the ball mill method and the magnetic chitosan microspheres are shown in Figure 3 . Figure 3a is an SEM image of iron sand at magnification

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

(PDF) Grinding in Ball Mills: Modeling and

2012年6月1日 The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Introduction F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in

New insights into ball-milled zero-valent iron composites

2023年1月20日 The iron powder, nickel powder, and quartz sand are mixed and added to a planetary ball mill for co-ball milling, which induces a mechanochemical reaction at room temperature to achieve effective degradation of PCNB (Zhang et al., 2013).

Synthesis of magnetite nanoparticles from iron sand by

2019年4月1日 Stable, hydrophylic magnetic nanoparticles have been obtained. • Direct use of iron (II) carboxymethylcellulose improves the synthesis. • The magnetic nanoparticles exhibit high spin–spin

Ball mills dry grinding systems fine powder processing

A ball mill is still the preferred solution for many types of dry grinding duty. A ball mill consists of a rotating horizontal cylinder, containing a cascading grinding media, typically steel or ceramic balls, in the range of 10 to 100 mm diameter. The grinding mechanism takes place within the falling and sliding grinding media. The feed

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball mill is 105 rpm. Using SEM characterization, the improved particles of silica sand presented a spherical shape with a cluster.

Mineral Processing, Equipment Manufacturers,

Mineral Processing, Equipment Manufacturers, Ball Mills, Flotation, Thickener Xinhai XINHAI EPC+M+O Strives to Provide the Optimized Solutions for Your Mine! News: Minexpo Time! Xinhai Mining is at

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

(PDF) Preparation of magnetic chitosan microspheres

2020年4月7日 Iron sand particles prepared by ball milling method have been used in the magnetic chitosan microspheres preparation. FTIR, XRD and SEM analyses were performed to characterize the magnetic...

(PDF) Grinding in Ball Mills: Modeling and

2012年6月1日 The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding

Ball Mill For Silica Sand,Grinding Ball Mill Machine Price

Ball Mill For Silica Sand,Grinding Ball Mill Machine Price Buy Ball Mill For Silica Sand,Grinding Ball Mill Machine,Mineral Grinding Ball Product on Alibaba Ways of Packing: ≤5h The average amount of time supplier took to respond to every buyer’s first message over the past 30 days. Alibaba Site: Tmall Taobao World Browse

New insights into ball-milled zero-valent iron composites

2023年1月20日 The iron powder, nickel powder, and quartz sand are mixed and added to a planetary ball mill for co-ball milling, which induces a mechanochemical reaction at room temperature to achieve effective degradation of PCNB (Zhang et al., 2013).

Synthesis of magnetite nanoparticles from iron sand by

2019年4月1日 Stable, hydrophylic magnetic nanoparticles have been obtained. • Direct use of iron (II) carboxymethylcellulose improves the synthesis. • The magnetic nanoparticles exhibit high spin–spin

Ball mills dry grinding systems fine powder processing

A ball mill consists of a rotating horizontal cylinder, containing a cascading grinding media, typically steel or ceramic balls, in the range of 10 to 100 mm diameter. The grinding mechanism takes place within the falling and sliding grinding media.

دعامات عالية للركام

كسارة متنقلة صغيرة لمعالجة الذهب

كان عدنه طحونه نبع المي

how much crushed granite in india

خطط ديي مصغرة مصنع غسل تعدين الذهب MTM محطم

قدرة طاحونة كرات الأسمنت في المملكة العربية السعودية

قدرت نانو ماشین سنگ زنی

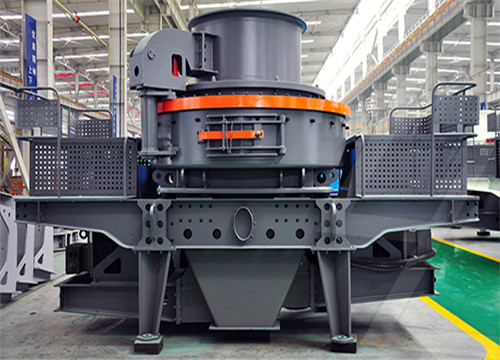

مخروط محطم VSI

كيف اصبح عامل منجم فحم بالصور

التعدين carlos vela tudela chancadora

تصنيع الرخام مصنع مسحوق في الهند

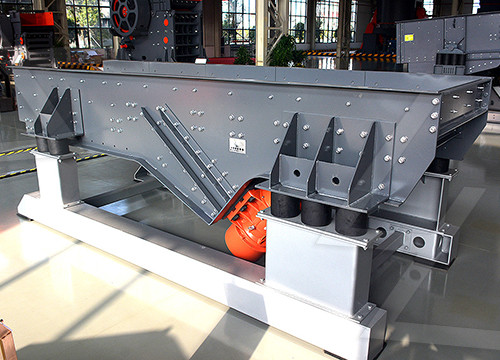

تهتز وحدة التغذية المصنوعة في الصين معدات التعدين

آلات لطحن الزيتون

ارتعاشی مفصل فیدر

كسارة فكية ناتجة 26x6

فیلم های کارخانه کارخانه ذی نفع جعبه جعبه

حزام النقل لرمل السيليكا

مطحنة الكرة الأربعاء للبيع في الصين

coveyor الحزام للحجر

حزام الناقل حزام الناقل الصانع

سحق المعادن مصنع آلة توفر تأثير محطم

ماكنات شطف واختبار مواسير

كينيا زجاجة محطم الزجاج في كينيا

الفحم معالجة مياه الصرف الصحي الألغام

شاشة المحمول السلطة ومحطم

آلة خام الذهب الصخري للرمل

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20