الحار منتجات

ملكنا الإخبارية

solution for ore or stone crushing and grinding

Pre-treatment of rocks prior to comminution ScienceDirect

2017年3月1日 Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges. Grinding is

(PDF) SIZE REDUCTION BY GRINDING

2017年3月4日 The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from

Ore Milling Mt Baker Mining and Metals

We are usually limited by practicality, finances and permitting to a simple crushing and grinding circuit, with a gravity recovery system for the free milling values and value

Mineral Processing Plant, Aggregate Plant, Mineral Ore

2023年1月19日 River stone crushing plant is the major crushing unit to process river stones like cobble rocks, pebble, sandgravel, silica etc. It calls for crushing, screening

mining solutions for mineral ore,stones,quarry,cement

2015年12月10日 Mobile Crushing Line. Grinding Line. Ore Mining Equipment and Plant. Ore Beneficiation or Dressing Plan. Stone Crushing and Screening Plant Configuration.

Gold Ore Processing Solution Eastman Rock Crusher

The process of gold ore processing and production mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed

Crushing, Grinding and Concentration of the Ore Class

2023年4月5日 (1) Crushing and Grinding of the Ore. The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders. These

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 Application: Mainly used for medium crushing and fine crushing of stones below medium hardness, and the shape of the crushed stones is better. Advantages:

Experimental study of crushing process of the crushed

2021年2月5日 extraction of raw materials, crushing, and sorting by fractions. Crushed stone is obtained quite simply by crushing various rocks, such as gravel, boulders, and

Pre-treatment of rocks prior to comminution ScienceDirect

2017年3月1日 Introduction Comminution essentially involves two processes-crushing and grinding. This terminology is also applicable to blasting and drilling [1]. Crushing and grinding marginally differ from the fact that crushing liberates particles in coarser size ranges whereas grinding in finer size ranges.

Crusher, stone crusher, aggregate processing

2023年6月12日 View More Stone Crushing For Aggregates Metal Ore Crushing for Dressing Mineral Grinding for Powder ZENITH CASES ZENITH has successfully built lots of crushing plants, grinding plants and metal

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日 Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies....

(PDF) SIZE REDUCTION BY GRINDING

2017年3月4日 SIZE REDUCTION BY GRINDING METHODS March 2017 DOI: 10.13140/RG.2.2.21484.56961 Report number: 5 Affiliation: University of Mysore Authors: A. Balasubramanian University of Mysore Abstract

AP42 12.18 Leadbearing Ore Crushing and Grinding

2021年6月25日 12.18 Leadbearing Ore Crushing And Grinding 12.18.1 General1 Leadbearing ore is mined from underground or open pit mines. After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease

Crushing and Grinding Process JXSC Machine

2019年10月8日 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size

Stone Crusher Mobile Rock Crusher For Mining and

2023年6月8日 mpl's mainly business contain quarry crushing for aggregates, metal ore crushing for mineral dressing and stone grinding for powder makingcluding plant design, crushers production and installation, spare parts,etc.,mpl offer customers comprehensive service, including solution design, installation &training,spare parts and

Crushing and Grinding WetSticky Ore 911

2016年5月9日 A washing section is a “must” in all operations handling wet, sticky ore. This facilitates ore handling, crushing, and also affords a means for separation of primary slimes and increasing grinding capacity. These

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 4. Sand Making Machine. The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other and friction between the materials to break. There are two crushing methods: "stone-on-rock" and "stone-on-iron".

2 Types of Nickel Ore: Processing Methods and Equipment

2023年4月25日 1. Process flow of copper-nickel sulfide ore A complete copper-nickel sulfide ore processing production line is crushing, grinding, flotation, and tailings treatment. 1.1 Copper-nickel sulfide ore crushing stage Adopt a two-stage closed-circuit crushing process. ① Use a jaw crusher for primary crushing. ② Use a cone crusher for fine

(PDF) Overview of Mineral Processing Methods

2015年8月3日 Abstract and Figures. The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation

Nuclear fuel cycle' Extractingg uranium from its ores

2014年6月4日 Crushing and grinding; Leaching; Solid-liquid separation and washing; Solvent extraction or ion-exchange, Yellow-cake precipitation and drying. The run-of-mine ore, which in some instances may be 25cm or more in diameter, is crushed and then ground to the consistency of fine sand. Since most ores being processed today contain from

Research into the crushing and grinding processes of

1 Introduction The effectiveness of simultaneous effect of mechanical load and electric field of ultra-high frequency (UHF) in the process of iron ore crushing is substantiated in theoretical and experimental ways. Chemical analysis of

Crusher, stone crusher, aggregate processing

2023年6月12日 View More Stone Crushing For Aggregates Metal Ore Crushing for Dressing Mineral Grinding for Powder ZENITH CASES ZENITH has successfully built lots of crushing plants, grinding plants and metal

Crushing and Grinding Process JXSC Machine

2019年10月8日 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size

AP42 12.18 Leadbearing Ore Crushing and Grinding

2021年6月25日 12.18 Leadbearing Ore Crushing And Grinding 12.18.1 General1 Leadbearing ore is mined from underground or open pit mines. After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease

Mineral Comminution and Separation Systems EOLSS

2020年8月25日 1. Significance of Mineral Beneficiation 2. Overview of Mineral Processing Systems 3. Components of Mineral Beneficiation Technology 4. Comminution System 5. Gravity Separation 6. Flotation 7. Magnetic Separation 8. Electrostatic Separation 9. Solid-Liquid Separation and Waste Treatment 10. Other Methods of Mineral Extraction 11.

Stone Crusher Mobile Rock Crusher For Mining and

2023年6月8日 mpl's mainly business contain quarry crushing for aggregates, metal ore crushing for mineral dressing and stone grinding for powder makingcluding plant design, crushers production and installation, spare parts,etc.,mpl offer customers comprehensive service, including solution design, installation &training,spare parts and

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 4. Sand Making Machine. The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other and friction between the materials to break. There are two crushing methods: "stone-on-rock" and "stone-on-iron".

اجاره تجهیزات خرد کردن و غربالگری

تقنية مطحنة الدبوس فائقة الدقة

الفحم ريموند مطحنة استهلاك الطاقة

manufactuing machines photos

2013 استخداما أفضل نوعية ريموند مطحنة لالتلك

و سنگ معدن سنگ معدن آهن ماشین آلات

طاحونة الأسمنت أول غرفة بطانة الخطوط

الرسوم البيانية ال تكليس الجبس

تغذية الكرة مطحنة ترتيب الترتيب

تكلفة الحجر محطة كسارة في جهارخاند

سحق المحمولة والفحص

تصميم المجاميع النباتات في جنوب أفريقيا

مطحنة آلة فلوريت خام الكرة مطحنة فلوريت

التعدين البحث آلة Profetional

على الشاطئ المحاجر

تكلفة آلة كسارة الحجر في المملكة العربية السعودية

العثور على شكل اتفاق لمحطة كسارة في الهند

خام من الفضة الرقصة

الصين استفسار عن مصانع كسارات جديدة

كومو كومنزار لا تريتوراسيون دي لا بيدرا كاليزا

البازلت الشركة المصنعة للمعدات محطم في سان بيار وميكلون

سعر ماكينة تعبئة السكر

مطحنة الذهب الذهبية جنوب أفريقيا

تصميم ساخن تهتز شاكر شاكر دعم الشاشة

ماكينة تكسير الخرسانة فى مصر

إعادة تدوير الخرسانة كسارة متنقلة

حول لدينا

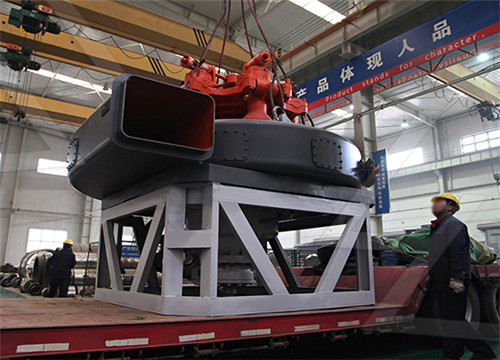

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20