الحار منتجات

ملكنا الإخبارية

industrial ball mills grinding middle size germany

Planetary Ball Mill PM 100 RETSCH highest

The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short grinding times. The PM 100

Ball Mills fritsch.de

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of medium-hard, soft, brittle, fibrous, temperature-sensitive and moist samples down to the finest

进一步探索Ball Mills Fritsch PDF Catalogs Technical DocumentationBall Mills Fritsch GmbH Milling and Sizing PDF Catalogs

Ball Mill RETSCH powerful grinding and homogenization

RETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard,

Ball mill, Ball grinding mill All industrial manufacturers

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Applications. Ball mills are found in settings as diverse as laboratories and

Effect of Grinding Media Size on Ferronickel Slag Ball

2021年12月27日 A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, i.e., 40, 25.4, and 12.7 mm and (ii) a mixed load of balls with

[PDF]

Grinding in Ball Mills: Modeling and Process Control

in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and the most commonly used

Industrial ball mill grinding middle size germany

Industrial ball mill grinding middle size germany. Some of the leading manufacturers of industrial ball mills in Germany include Fritsch GmbH, Retsch GmbH, and Netzsch

sbm industrial ball mills grinding middle size germany.md

Open sidebar. chengxinjia; sbm; Repository

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials. In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials.

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process know-how. This is because the efficiency of a mill depends on its internals. All parts of the mill, the diaphragm, the shell lining and the ball charge, have been continuously developed in-house for nearly a century, which is the basis of

Ball mill, Ball grinding mill All industrial manufacturers

ball grinding mill L14 series. with rods horizontal stone. Rotational speed: 42 rpm 69 rpm. Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. Ball /Rod

Ball Mills Ball Mill Ball Milling Orbis Machinery

Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and

[PDF]

Grinding in Ball Mills: Modeling and Process Control

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

[PDF]

Wear ofgrinding media in the mineral processing

2018年11月9日 This stone was written in order to provide the grinding media user with some tools and insight on how to evaluate grindingmedia.The primaryfocus ison grindingballs,but the same analysis can be applied to grinding rods. The wear law for grinding mediais discussed,and the relationship between MINERALS

Grinding Mill DesignBall Mill Manufacturer

2017年2月20日 Grinding MillBall Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common

Mill, Grinding mill All industrial manufacturers

rotor mill GSL 180 series. horizontal for stainless steel. Final grain size: 1 mm. Rotational speed: 150 rpm. Output: 50 kg/h 200 kg/h. The slow speed granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm. The rotor is directly driven by a geared motor.

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials. In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials.

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

The diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production output. This is because the ratio of the diameter to the grinding path length determines the residence time of the material in the mill and thus the theoretically achievable fineness of the material at the discharge.

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and

Manufacturer producer grinding balls Europages

Browse through 38 Manufacturer producer in the grinding balls industry on Europages, a B2B platform for finding worldwide partners. HUAMIN can supply grinding balls produced to your required size and chemical composition. We have got the certificates as follows: ISO9001: 2008, ISO14001: 2004, GB/T28001-2001(OHSAS18000)2. such as stone

[PDF]

Grinding in Ball Mills: Modeling and Process Control

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

[PDF]

Wear ofgrinding media in the mineral processing

2018年11月9日 This stone was written in order to provide the grinding media user with some tools and insight on how to evaluate grindingmedia.The primaryfocus ison grindingballs,but the same analysis can be applied to grinding rods. The wear law for grinding mediais discussed,and the relationship between MINERALS

Grinding Mill DesignBall Mill Manufacturer

2017年2月20日 The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills).

Mill, Grinding mill All industrial manufacturers

rotor mill GSL 180 series. horizontal for stainless steel. Final grain size: 1 mm. Rotational speed: 150 rpm. Output: 50 kg/h 200 kg/h. The slow speed granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm. The rotor is directly driven by a geared motor.

[PDF]

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

2021年7月31日 2.6.1 Ball size distribution in tumbling mills 37 2.6.2 Milling performance of a ball size distribution 40 2.7 Summary 41 Chapter 3 Experimental equipment and programme 43 3.1 Laboratory grinding mill configuration 43 3.2 Preparation of mono-size grinding media 44 3.3 Feed material preparation 46 3.3.1 Coal sample collection at

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently

Ball Mill RETSCH powerful grinding and homogenization

RETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard,

Ball mill, Ball grinding mill All industrial manufacturers

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Applications. Ball mills are found in settings as diverse as laboratories and

Effect of Grinding Media Size on Ferronickel Slag Ball

2021年12月27日 A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, i.e., 40, 25.4, and 12.7 mm and (ii) a mixed load of balls with

Grinding in Ball Mills: Modeling and Process Control

in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and the most commonly used

Industrial ball mill grinding middle size germany

Industrial ball mill grinding middle size germany. Some of the leading manufacturers of industrial ball mills in Germany include Fritsch GmbH, Retsch GmbH, and Netzsch

sbm industrial ball mills grinding middle size germany.md

Open sidebar. chengxinjia; sbm; Repository

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials. In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials.

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process know-how. This is because the efficiency of a mill depends on its internals. All parts of the mill, the diaphragm, the shell lining and the ball charge, have been continuously developed in-house for nearly a century, which is the basis of

Ball mill, Ball grinding mill All industrial manufacturers

ball grinding mill L14 series. with rods horizontal stone. Rotational speed: 42 rpm 69 rpm. Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. Ball /Rod

Ball Mills Ball Mill Ball Milling Orbis Machinery

Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and

Grinding in Ball Mills: Modeling and Process Control

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Wear ofgrinding media in the mineral processing

2018年11月9日 This stone was written in order to provide the grinding media user with some tools and insight on how to evaluate grindingmedia.The primaryfocus ison grindingballs,but the same analysis can be applied to grinding rods. The wear law for grinding mediais discussed,and the relationship between MINERALS

Grinding Mill DesignBall Mill Manufacturer

2017年2月20日 Grinding MillBall Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common

Mill, Grinding mill All industrial manufacturers

rotor mill GSL 180 series. horizontal for stainless steel. Final grain size: 1 mm. Rotational speed: 150 rpm. Output: 50 kg/h 200 kg/h. The slow speed granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm. The rotor is directly driven by a geared motor.

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials. In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials.

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

The diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production output. This is because the ratio of the diameter to the grinding path length determines the residence time of the material in the mill and thus the theoretically achievable fineness of the material at the discharge.

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and

Manufacturer producer grinding balls Europages

Browse through 38 Manufacturer producer in the grinding balls industry on Europages, a B2B platform for finding worldwide partners. HUAMIN can supply grinding balls produced to your required size and chemical composition. We have got the certificates as follows: ISO9001: 2008, ISO14001: 2004, GB/T28001-2001(OHSAS18000)2. such as stone

Grinding in Ball Mills: Modeling and Process Control

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Wear ofgrinding media in the mineral processing

2018年11月9日 This stone was written in order to provide the grinding media user with some tools and insight on how to evaluate grindingmedia.The primaryfocus ison grindingballs,but the same analysis can be applied to grinding rods. The wear law for grinding mediais discussed,and the relationship between MINERALS

Grinding Mill DesignBall Mill Manufacturer

2017年2月20日 The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills).

Mill, Grinding mill All industrial manufacturers

rotor mill GSL 180 series. horizontal for stainless steel. Final grain size: 1 mm. Rotational speed: 150 rpm. Output: 50 kg/h 200 kg/h. The slow speed granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm. The rotor is directly driven by a geared motor.

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

2021年7月31日 2.6.1 Ball size distribution in tumbling mills 37 2.6.2 Milling performance of a ball size distribution 40 2.7 Summary 41 Chapter 3 Experimental equipment and programme 43 3.1 Laboratory grinding mill configuration 43 3.2 Preparation of mono-size grinding media 44 3.3 Feed material preparation 46 3.3.1 Coal sample collection at

industrial ball mills grinding middle size germany

2022年2月14日 Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently

كسارات صخور مصر للبيع أو الإيجار

سعر كسارة مخروطية محمولة على المسار

كيف يتم استخراج الفحم ومعالجتها

شركة بيع كسارات باالمملكة العربية السعودية

مصانع الاسمنت في شيتور

digunakan statis grizzly pemisah batu

اسعار المعدات الثقيلة جديد ومستعمل

لفة كسارة الصخور الصلبة

كلف تعدين اليمن الاتصال

أحجار الرحى طحن

آلات تصنيع الرمل قضيب 86

الاسمنت طحن الرأسي مطحنة الصين

مصنع معالجة الذهب الجاف

المطاحن العتيقة المطاحن الصور

محطم في فيانا دو كاستيلو بيع

سنگ شکن شن و ماسه و ماشین از جا در رفته را با آب refing

بودرة التلك وطحن

تكاليف التركيب محطم مقارنات

استخراج رمل الحجر الجيري

معدات تجهيز الذهب yemensand معدات الإنتاج

تكلفة تأثير محطم للتعدين

وحدات معالجة الذهب ، معدات تعدين الذهب

desighn مخروط محطة كسارة

كسارة الحجر آلة بيع NEDERLAND

له کننده در کیش

مطاحن pulversing meneral المحدودة

حول لدينا

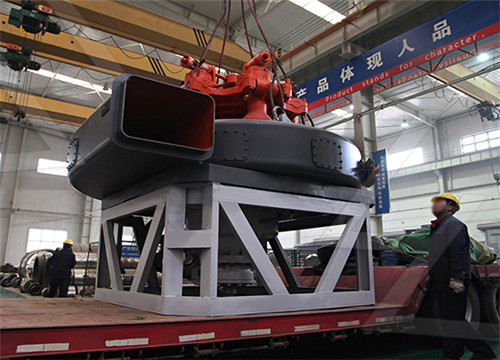

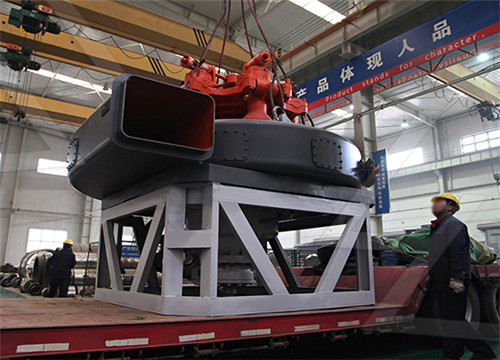

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20