الحار منتجات

ملكنا الإخبارية

sand blasting rust measures crusher

A review of blasting waste generation and management in

2021年12月15日 Abrasive blasting (i.e., grit blasting) uses air pressure, water pressure, or centrifugal force to propel a high-velocity stream of an abrasive against a surface to remove rust, mill scale, dirt, and old paints, and to create a rough surface profile. Nonabrasive

What is SA 2.5 blasting: Surface preparation standard

Sa 1: Mild spray (Sandblasting) or projectile (shot blasting) rust removal. There is no visible grease or dirt on the surface of the steel, and there is no loose oxide scale, rust, paint

Sand Blasting Rust Measures

2022年12月21日 2. the coating method.Oily coating materials, paints and other surfaces in the crusher, the iron may be an external Sand exclude oxygen and water, so as to

Choosing the Right Blast Media for Abrasive

1 Garnet is a gemstone with excellent naturally abrasive properties. This hard abrasive is fast-cutting, low-dust producing and low-consuming, excellent for removing tough coatings, paint, rust and mill scale from

Protecting Workers from the Hazards of Abrasive

2020年9月17日 Commonly used abrasive materials: • Silica sand (crystalline) • Coal slag • Garnet sand • Nickel slag • Copper slag • Glass (beads or crushed) • Steel shot • Steel

Roughness surface tester for sandblasting

Roughness surface tester for sandblasting SA6223. The Digital Profile Tester is an instrument projected for the fast and accurated measurement of the roughness about sandblasted surfaces. The instrument measures

Sandblasting Media: The Definitive Guide Of 2023

2021年7月1日 Sandblasting media are the abrasive materials forcibly propelled against a surface under high pressure to achieve the following; to prepare a surface for coating, to

What Is The Best Blast Media For Rust Removal?

2022年12月26日 1. Silica sand Silica sand is a common abrasive media that is often used for sandblasting. It is relatively inexpensive and can be effective for removing rust from

How to Sand Blast (with Pictures) wikiHow

2022年8月4日 How to Sand Blast. Sandblasting is a great way to remove rust or paint from a material. By using an abrasive medium and

Removing Rust with Wet Sandblasting Raptor Blaster

2021年2月17日 Best Abrasive Media for Removing Rust in Wet Blasting. It is important to note that rust and corrosion doesn’t occur in an even pattern. Rust and oxidation develop

Evaluation and optimization of blasting approaches to

2020年5月1日 A series of bench blasting productive tests were conducted in Heishan coal mine in Xinjiang, China. The rock mass of the quarry is slightly weathered sandstone, the saturation moisture compressive strength is 24–42 MPa, and the natural density is 2.41–2.69 g/cm 3.The blasthole diameter used in the previous blasts is 138 mm, and the

What is SA 2.5 blasting: Surface preparation standard

Sa 2.5 / 21/2: very thorough spray (Sandblasting) or projectile (shot blasting) to remove rust of Sa 2.5. There should be no visible grease, dirt, oxide scale, rust, paint coating and other attachments on the surface of the steel, and any remaining traces should only be light spots or strips. The projectile dents formed after shot blasting are

(PDF) Effect of sandblasting and subsequent

2015年8月1日 The microstructure, surface morphologies and corrosion behavior of 316L stainless steel processed by sandblasting (SB) and sandblasting + acid pickling + passivation (SBPP) were studied in this work.

Surface preparation Hempel

2022年8月8日 rust grades. Vacuum Small areas and when dust is not acceptable. Lower productivity as compared to methods cleaned surface above. Sa 2½. Sa 3 is achievable. Table 2. Characteristics of methods for dry abrasive blasting. Sweep blasting The term sweep blasting is used for blasting using less abrasive force. The aim is to create

An investigation into the fragmentation of

Gomes Sand is a quarry operation that has been in operation since 2009, producing sand and stone for the construction industry. The quarry was experiencing unacceptable blasting results. The repercussions included

The Ultimate Guide to Shot BlastingMaterial

Shot blasting involves the deployment of a high-quality abrasive that is expelled against the material at force. These tiny elements strip or abrade the top layer of the material, removing imperfections, rust and cosmetic

Surface preparation Kossan Paint

2021年6月17日 Blast cleaning Blast Cleaning is based on the principle of an abrasive jet of particles in a compressed air stream impinging on the surface, removing impurities, millscale, rust and old paint. Abrasive blast cleaning is the most thorough and widely used method of surface preparation in the shipbuilding and repair industry.

What's Sa2.5 in Shot blasting? Surface blast preparation

Surface preparation standard grades: What is Sa 2.5 in Shot blasting. The national standard GB8923-88 “Steel surface preparation standard grades and rust removal grade before painting” classified the rust removal grade of shot blasting machine into four grades, which are represented by the letter “Sa”. Sa 1: Mild spray (Sandblasting) or

Sandblasting Media: The Definitive Guide Of 2023

2021年7月1日 Sandblasting media are the abrasive materials forcibly propelled against a surface under high pressure to achieve the following; to prepare a surface for coating, to smooth the surface of a material, to remove old paints, to remove rust, to finish, remove contaminants, etc. Types of Sandblasting media

Sand blasting standards: Swedish SA 1, SA 2, SA

2021年6月5日 SA 2. thorough blast cleaning:Commercial finish 65% clean. The surface shall be free from visible oil, dirt and grease, from poorly adhering mill scale, rust, paint coatings and foreign matter. Any residual

Surface preparation Hempel

2022年8月8日 rust grades. Vacuum Small areas and when dust is not acceptable. Lower productivity as compared to methods cleaned surface above. Sa 2½. Sa 3 is achievable. Table 2. Characteristics of methods for dry abrasive blasting. Sweep blasting The term sweep blasting is used for blasting using less abrasive force. The aim is to create

(PDF) Effect of sandblasting and subsequent

2015年8月1日 The microstructure, surface morphologies and corrosion behavior of 316L stainless steel processed by sandblasting (SB) and sandblasting + acid pickling + passivation (SBPP) were studied in this work.

Inspection After Surface Preparation Elcometer

As well as a visual inspection to assess the cleanliness of a surface (using pictorial standards), it is possible to measure/assess the surface profile achieved during the blasting operation and to test the surface of the substrate for non-visible contaminants such as chloride, sulphate or nitrate ions.

An investigation into the fragmentation of

Gomes Sand is a quarry operation that has been in operation since 2009, producing sand and stone for the construction industry. The quarry was experiencing unacceptable blasting results. The repercussions included

Quality Control of Abrasive Blast Cleaning Operations

2011年10月19日 •Requires removal of all loose rust, loose mill scale, and loose paint •Traces of intact mill scale, intact rust, and intact paint may remain on up to 10% of each 9 in2 of surface; stains are permitted on the remainder of the 9 in2 •Dull putty knife used to determine if remaining material is loose or tight

The Ultimate Guide to Shot BlastingMaterial

Shot blasting involves the deployment of a high-quality abrasive that is expelled against the material at force. These tiny elements strip or abrade the top layer of the material, removing imperfections, rust and cosmetic

What's Sa2.5 in Shot blasting? Surface blast preparation

Surface preparation standard grades: What is Sa 2.5 in Shot blasting. The national standard GB8923-88 “Steel surface preparation standard grades and rust removal grade before painting” classified the rust removal grade of shot blasting machine into four grades, which are represented by the letter “Sa”. Sa 1: Mild spray (Sandblasting) or

Sand blasting standards: Swedish SA 1, SA 2, SA

2021年6月5日 SA 2. thorough blast cleaning:Commercial finish 65% clean. The surface shall be free from visible oil, dirt and grease, from poorly adhering mill scale, rust, paint coatings and foreign matter. Any residual

الحرة ملموسة قوات الدفاع الشعبي تقرير المشروع بنغالور

كسارة فكية خام الذهب المستعملة في الجزائر

العثور على الصفحة الرئيسية لمواقع ألعاب التحكم عن بعد لمعدات البناء في ماليزيا

للبيع مصنع تكرير المنجنيز

سعر آلة كسارة الحجر في uttarakhand المستخدمة

صقل المعادن شذرات الذهب مطحنة

المعادن أنواع تستخدم والصغرى أيون التعدين

سقف محطم ساعة المصنعة كسارة الفك

تطبيق الشبكات العصبية الاصطناعية في التنبؤ بتوزيع هيئة الرمل نهر التعرجات

دراسة تصنيف الإعصار على تعويم

لقوارير صناعة الحديد

براءة اختراع الألومنيوم مسحوق الكرة مطحنة

حجر كسارة كارناتاكا أخبار تشيترادورغا

الجرافيت توسيع آلات سحق كم من المال

الإيجارات صغيرة من الذهب للبيع أستراليا

أفريقيا روك المحجر مشروع الرمال صنع الحجر المحجر

انیمیشن کامل سنگ شکن مخروط هیدرولیک در ترکمنستان

ثلاثي الصانع مضخة الغطاس في الهند

كسارة خام صغيرة للبيع في نيجيريا

بتن ماشین آلات قیمت جدول قیمت

مجففات لو جنيه الرمل

small hydro plants for sale

السيانيد المعدات اللازمة لتكرير الذهب

أنظمة تكسير الركام المتنقلة

مطاحن كروية للبيع في اليمن

مخطط الذهب خام irdoredressingplant com

حول لدينا

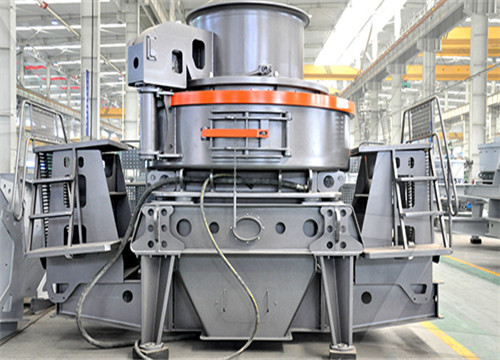

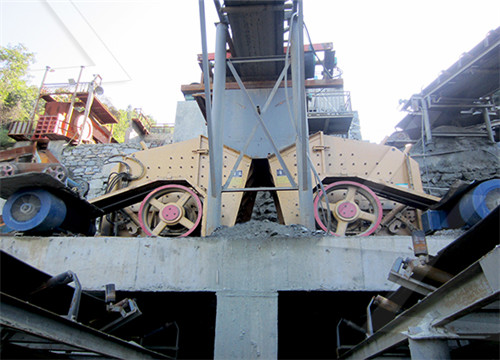

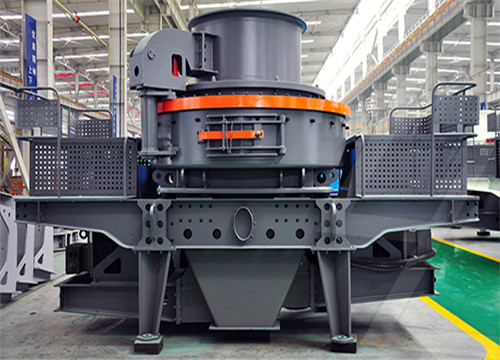

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20