الحار منتجات

ملكنا الإخبارية

grinding media consumption in cement production

Analysis of material flow and consumption in cement

2016年1月20日In 2011, the world cement production was approximately 3.60 Bt/3.30 Bt (clinker) ( U.S.G.S., U.S.Geological Survey. 2014 ), requiring more than 3.00 Bt of limestone for the manufacture of clinker ( Schneider et al., 2011 ). However, large material flows

(PDF) Analysis of material flow and consumption in cement

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material

Cement Analysis IEA International Energy Agency

Key strategies to cut carbon emissions in cement production include improving energy efficiency, switching to lower-carbon fuels, promoting material efficiency (to reduce the

进一步探索Cement: 2023 World Market Review and Forecast to 2032Global cement industry statisticsfacts Statista

Grinding Media Market Report Global Forecast From

2019年11月4日Cement plant : In the cement industry, grinding media is used to process clinker, gypsum, natural gas or coal, limestone, and other ingredients in order to produce

4,8/5

Modeling of energy consumption factors for an industrial cement

2022年5月9日Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's

(PDF) Cement grinding optimisation ResearchGate

2004年11月1日The current world consumption of cement is about 1.5 billion tonnes per annum and it is increasing at about 1% per annum. The electrical energy consumed in

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日Cement production is an energy intensive process. Grinding is a high-cost operation consuming approximately 60% of the total electrical energy expenditure in

Consumption of steel grinding media in mills A review

2013年8月1日Grinding media consumption is one of the major operating costs in mineral processing industry; it was found that the consumption of media in ball mills

Consumption of steel grinding media in mills A review

2013年8月1日Grinding circuit operators have long been aware of the significant impact of grinding media consumption on the cost of grinding. Comminution

Grinding Media Consumption In Cement Production

2022年3月7日The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power

Cement grinding optimisation ScienceDirect

2004年11月1日The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding. There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved.

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding...

Grinding Media Market Report Global Forecast From 2022 To 2030

Cement plant : In the cement industry, grinding media is used to process clinker, gypsum, natural gas or coal, limestone, and other ingredients in order to produce portland cement which will then be used in the construction sector. Power plant :

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower operating costs per unit of production Optimization can also reduce the cost of . liners and grinding media.

Efficiency of Using Small Diameter Grinding Balls for Cement Grinding

2022年10月14日According to VNTP 06-91 (Departmental Norms of Production Engineering) [ 2 ], the rates of consumption of grinding balls during the production of 1 t of cement were specified, including for the first chamber of the mill, consumption of balls with diameter of 50–100 mm is up to 0.70 kg, and for the second chamber,

Cement mill Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

The Choice Of Grinding Media

2016年12月28日Grinding media is the main component in the technological process of grinding materials for cement production, electric power, glass, silicate products, at the extraction of the concentrate for

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日The current world consumption of cement is about 1.5 billion tonnes per annum and it is increasing at about 1% per annum. The electrical energy consumed in cement production is approximately

POWERING THE CEMENT INDUSTRY CEMBUREAU

Total electricity consumption in a dry process is split into equal parts between raw material preparation and clinker production (25% each), then 43% for cement grinding and the remaining for raw material extraction, fuel grinding and for packing and loading.

Modernizing cement manufacturing in China leads to

2022年11月17日Looking at the global electricity consumption of cement production (Fig. 4b), Canada and the U.S. appeared as the top two countries, with more than 130 kWh t −1 of cement in 2018 due to the

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower operating costs per unit of production Optimization can also reduce the cost of . liners and grinding media.

Modeling of energy consumption factors for an industrial cement

2022年5月9日12 Citations 2 Altmetric Metrics Abstract Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a...

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

The Choice Of Grinding Media

2016年12月28日Grinding media is the main component in the technological process of grinding materials for cement production, electric power, glass, silicate products, at the extraction of the concentrate for

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日Cement ball mill Authors: Khairullah Azooz Abstract and Figures The problem addressed by this research is how to increase the production of cement mills in the Kufa cement plant when...

`Grinding Aid Effectiveness in Cement Ball Mill

Grinding Aid well contribute in decreasing the agglomerated substance (coating) above the balls, increasing the grinding efficiency of the mill and improve the flow characteristics of Introduction cement with preventing

Optimization of Cement Grinding Operation in Ball

2016年7月18日The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries. It is costly and an inefficient process in terms of energy requirements and steel consumption related to grinding media and liners. Spherical grinding media are predominantly used in final stages of ore grinding.

Grinding Media Market Report Global Forecast From

2019年11月4日Cement plant : In the cement industry, grinding media is used to process clinker, gypsum, natural gas or coal, limestone, and other ingredients in order to produce

Modeling of energy consumption factors for an industrial cement

2022年5月9日Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's

(PDF) Cement grinding optimisation ResearchGate

2004年11月1日The current world consumption of cement is about 1.5 billion tonnes per annum and it is increasing at about 1% per annum. The electrical energy consumed in

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日Cement production is an energy intensive process. Grinding is a high-cost operation consuming approximately 60% of the total electrical energy expenditure in

Consumption of steel grinding media in mills A review

2013年8月1日Grinding media consumption is one of the major operating costs in mineral processing industry; it was found that the consumption of media in ball mills

Consumption of steel grinding media in mills A review

2013年8月1日Grinding circuit operators have long been aware of the significant impact of grinding media consumption on the cost of grinding. Comminution

Grinding Media Consumption In Cement Production

2022年3月7日The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power

Cement grinding optimisation ScienceDirect

2004年11月1日The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding. There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved.

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding...

Grinding Media Market Report Global Forecast From 2022 To 2030

Cement plant : In the cement industry, grinding media is used to process clinker, gypsum, natural gas or coal, limestone, and other ingredients in order to produce portland cement which will then be used in the construction sector. Power plant :

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower operating costs per unit of production Optimization can also reduce the cost of . liners and grinding media.

Efficiency of Using Small Diameter Grinding Balls for Cement Grinding

2022年10月14日According to VNTP 06-91 (Departmental Norms of Production Engineering) [ 2 ], the rates of consumption of grinding balls during the production of 1 t of cement were specified, including for the first chamber of the mill, consumption of balls with diameter of 50–100 mm is up to 0.70 kg, and for the second chamber,

Cement mill Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

The Choice Of Grinding Media

2016年12月28日Grinding media is the main component in the technological process of grinding materials for cement production, electric power, glass, silicate products, at the extraction of the concentrate for

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日The current world consumption of cement is about 1.5 billion tonnes per annum and it is increasing at about 1% per annum. The electrical energy consumed in cement production is approximately

POWERING THE CEMENT INDUSTRY CEMBUREAU

Total electricity consumption in a dry process is split into equal parts between raw material preparation and clinker production (25% each), then 43% for cement grinding and the remaining for raw material extraction, fuel grinding and for packing and loading.

Modernizing cement manufacturing in China leads to

2022年11月17日Looking at the global electricity consumption of cement production (Fig. 4b), Canada and the U.S. appeared as the top two countries, with more than 130 kWh t −1 of cement in 2018 due to the

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower operating costs per unit of production Optimization can also reduce the cost of . liners and grinding media.

Modeling of energy consumption factors for an industrial cement

2022年5月9日12 Citations 2 Altmetric Metrics Abstract Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a...

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

The Choice Of Grinding Media

2016年12月28日Grinding media is the main component in the technological process of grinding materials for cement production, electric power, glass, silicate products, at the extraction of the concentrate for

(PDF) IMPROVING PRODUCTIVITY BASED ON THE MOVEMENT OF

2019年12月25日Cement ball mill Authors: Khairullah Azooz Abstract and Figures The problem addressed by this research is how to increase the production of cement mills in the Kufa cement plant when...

`Grinding Aid Effectiveness in Cement Ball Mill

Grinding Aid well contribute in decreasing the agglomerated substance (coating) above the balls, increasing the grinding efficiency of the mill and improve the flow characteristics of Introduction cement with preventing

Optimization of Cement Grinding Operation in Ball

2016年7月18日The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries. It is costly and an inefficient process in terms of energy requirements and steel consumption related to grinding media and liners. Spherical grinding media are predominantly used in final stages of ore grinding.

أجزاء كسارة الفك العالمي

جس كسارة الفك سلسلة

رسالة كسارة الفك كولينيت

تستخدم كسارة محجر الحجر للبيع الرمال جعل حجر المحاجر

تكلفة محجر كسارة الصخور عمان

3 در 1 دستگاه گیاهان غربالگری سنگ

16 × 20 الارز كسارة الفك

الصين 5 طاحونة

خط انتاج الكروسا الالي

fungsi المحجر تفريغ شاحنة

تجربة نموذج شهادة لطحن الرخام

أبعاد كسارة مخروط 54rc جاي

معدات التعدين Sauth Africa

غابة كومبي كبيرة لطحن romar

الحزام الناقل للبيع في ماليزيا تستخدم

كسارة التعدين

المعدات في المحجر

آلة طحن ro الربيع التجنيب

أدوات إحصائية لآلات كسارة الحجارة أدوات إحصائية لتعدين

اوج کارخانه سیمان

سوق المحاجر والكسارات

تولید تولید کننده نوار نقاله

عدد الكسارات الجرانيت هي في الولايات المتحدة الأمريكية

قنبر المعدنية

مطحنة المهنية المحفوظات الخدمة

1mm تمزيق الحجر للعمل ملموسة

حول لدينا

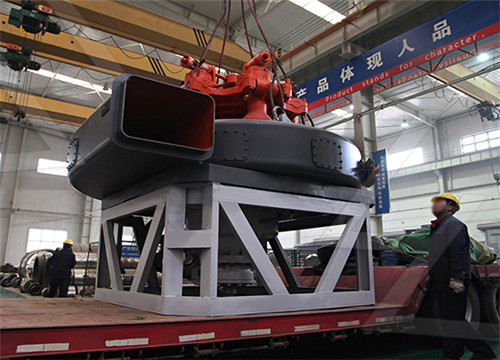

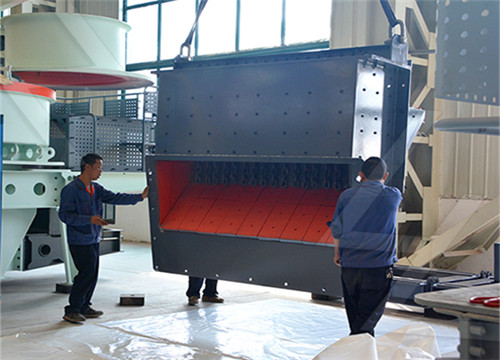

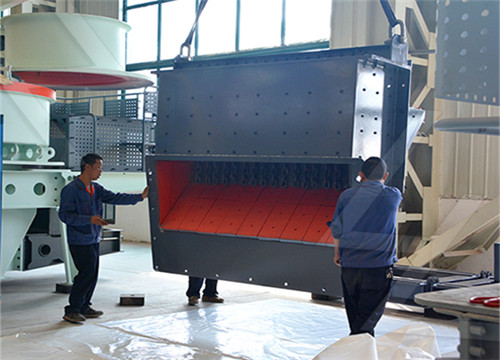

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20