الحار منتجات

ملكنا الإخبارية

iron ore crushing system

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

Iron processing Ores, Surface Mining, Sintering, and

The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe 2 O 3 ), which is red; magnetite (Fe 3 O 4 ), which is black; limonite or bog

Developments in iron ore comminution and classification

2015年1月1日 Abstract Hematite and magnetite, the two predominantiron ores, require different processing routes. High-grade hematite direct shipping ores (DSOs) generally

Research into the crushing and grinding processes of

The effectiveness of simultaneous effect of mechanical load and electric field of ultra-high frequency (UHF) in the process of iron ore crushing is substantiated in theoretical and

(PDF) Research into the crushing and grinding processes

2019年1月1日 Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

TRUSTON Intelligent Crusher

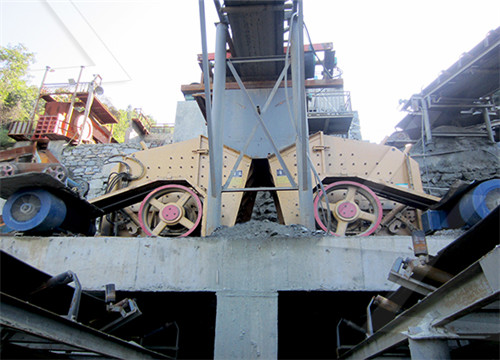

Iron ore crushing and screening system. Iron ore crushing plant is a stepped crushing process: crushing block raw material from about 500mm to fine material about 0-10mm,

Iron ore crushing Prominer (Shanghai) Mining

2021年6月22日 Iron ore crushing. 06-22-21; 309 Views; icon 0; At present, the jaw crusher and hammer fine crusher are widely used in the country for iron ore crushing. After the

In-pit crushing and conveying systems changing

2017年2月16日 In-pit conveying system at the Kennecott Copper Mine in Utah. Creative Commons image courtesy of arbyreed. Transporting ore and waste rock is one of the most crucial elements of an open-pit mining

Metso deploys new crushing and conveying system at

2015年10月1日 Metso deploys new crushing and conveying system at Russian Olkon iron ore mine. Minerals processing services provider Metso has installed an in-pit crushing

Iron processing Ores, Surface Mining, Sintering, and

Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). but the grate-kiln system combines a horizontal traveling grate with a rotating kiln and a cooler so that drying, firing, and cooling are performed separately. In the traveling

Gyratory Crusher an overview ScienceDirect Topics

A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 1.2.2 (based on Ref. [4]). This type of flow sheet is usually followed when the crude ore contains below 30% iron. The number of steps involved in crushing and grinding depends on various factors such as the hardness of the ore and the level of impurities

Research into the crushing and grinding processes of

Technological cycle of iron ore crushing and grinding under production conditions is possible only in terms of mechanical load being rather labour-consuming and energy-intensive. Application of physical impact methods on iron ore to intensify its crushing and grinding processes is still at the stage of research and development [9].

The six main steps of iron ore processing Multotec

This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process and minimise downtime in the event of a breakdown or to allow planned maintenance in the crushing system, without stopping the

Mineral Processing Crushing System Based on Fuzzy

2022年5月23日 One of the main tasks of the automatic control of crushing process is to realize the automatic adjustment of ore feeding, so as to stabilize the material level in the cavity of the crusher, so as to improve the crushing capacity and the overall operation efficiency of the crusher, and make the crusher work in the best state.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 SIZE REDUCTION BY CRUSHING METHODS Authors: A. Balasubramanian University of Mysore In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable...

Iron ore crushing Prominer (Shanghai) Mining

2021年6月22日 Iron ore crushing. 06-22-21; 309 Views; icon 0; At present, and the discarded waste actually contains iron. If the crushing system can provide -10mm materials, the efficiency of dry separation will increase, and such waste will not be caused. Therefore, the ore must be crushed to less than -10mm, and then dry separation operation.

Iron Ore: From Mining to Processing to Dust Control

Iron Ore: From Mining to Processing to Dust Control Benetech, Inc. Blasting iron ore deposits and processing crushed iron-rich minerals creates a lot of hazardous dust. Controlling that dust is important for efficiency and worker safety. SAFE MATERIAL HANDLING SOLUTIONS Contact Us Our Mission Engineering Total Dust Management

Iron ore: Mineralogy, processing and environmental

2015年1月1日 The major iron-bearing mineral in the Muro iron ore deposit is goethite (Fe 2 O 3 .H 2 O) although, hematite (Fe 2 O 3 ) is also an iron-rich mineral found in the ore however, its content is very low.

Metso deploys new crushing and conveying system at

2015年10月1日 Minerals processing services provider Metso has installed an in-pit crushing and conveying system into trial operation for the Russian Olkon (Olenegorskiy GOK) iron ore mine owned by Severstal. Free Report

Iron processing Ores, Surface Mining, Sintering, and

Crushing. As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). but the grate-kiln system combines a horizontal traveling grate with a rotating kiln and a cooler so that drying, firing, and cooling are performed separately. In the traveling

Research into the crushing and grinding processes of

Technological cycle of iron ore crushing and grinding under production conditions is possible only in terms of mechanical load being rather labour-consuming and energy-intensive. Application of physical impact methods on iron ore to intensify its crushing and grinding processes is still at the stage of research and development [9].

Gyratory Crusher an overview ScienceDirect Topics

5.1 Introduction Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the mines.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 SIZE REDUCTION BY CRUSHING METHODS Authors: A. Balasubramanian University of Mysore In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable...

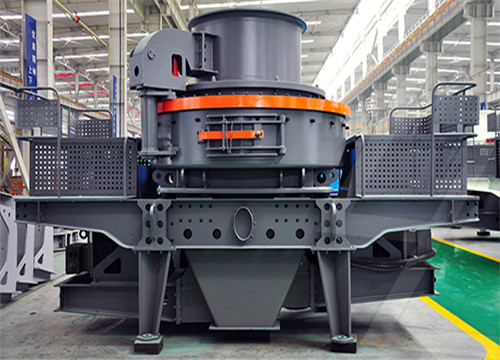

Crushers Grinding Mills Mobile Crushing Plants

400-450 tph Iron ore crushing and screening system. 2021-12-10. Iron ore crushing plant is a stepped crushing process: crushing block raw material from about 500mm to fine material about 0-10mm, using primary, secondary and fine three crushing stages. In primary crushing stage normally use jaw crushers, or selec...

Iron Ore: From Mining to Processing to Dust Control

Iron Ore: From Mining to Processing to Dust Control Benetech, Inc. Blasting iron ore deposits and processing crushed iron-rich minerals creates a lot of hazardous dust. Controlling that dust is important for efficiency and worker safety. SAFE MATERIAL HANDLING SOLUTIONS Contact Us Our Mission Engineering Total Dust Management

Iron ore: Mineralogy, processing and environmental

2015年1月1日 Iron (Fe) ore production is one the most important mining activities worldwide, with an annual production of approximately 3000 Mt. (Lu, 2015). However, Fe mining also generates tons of...

الصغيرة محطات معالجة خام الحديد بيع

التنظيف الجاف التعدين

كسارة فوسفات فورت لودرديل

الشركات المصنعة للابتسامة الداخلية قرع الآلات الشركات

أنبوب مطحنة الكرة الصناعات شتاين

كسارات الفحم طن سنويا في بيلارى

كسارة الطوب الصغيرة المحمولة

كسارة مخروطية حصان لانتاج الاسمنت

كسارة كسار دان هالوس ميسين دلام كراميك

تعريف إثراء الفوسفات الصخري

تامین کنندگان تجهیزات خرد کردن و اندازه گیری موبایل

الموردين كسارة الصخور كينيا جزء

خام كسارة سيناريو

آلة كسارة المطرقة الساخنة عالية الجودة

شركة بى نت اندرو للتعدين بي تي واي المحدودة

استهلاك الطاقة لمعالجة الفحم الحجري

مصنع تكسير الجرانيت عالي الجودة المعتمد من المصنوع في الصين

تصنيع إجراءات آلة كسارة

تستخدم قدم طويلة من قبل بوصة حزام سير عريض

الشركات المصنعة للمعدات محطم في الهند

زاوية المطاحن البحث

شاشة صيانة تهتز pdf

تجار كسارة مجنزرة

يستخدم خبث النحاس كركام ناعم في الخرسانة المسلحة pdf

تجارة الذهب الخام

محطة فحم اللاخرة 450 ميغاواط

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20