الحار منتجات

ملكنا الإخبارية

Jaw crusher needs dust collection

Laboratory and pilot plant Primary Jaw Crushers

Jaw Crusher an overview ScienceDirect Topics

1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual

进一步探索Jaw Crusher ComponentsParts Mineral ProcessingEstimate Jaw Crusher Capacity Mineral Processing

HSE Quarries Safe operation and use of mobile jaw

The quarry health and safety document. Useful links. Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition

进一步探索risk assessment on jaw crusher MiningQuarry PlantSafety Operation Procedures of Crusher Luoyang Dahua

Fine Jaw Crushers

Essa® JC1250 Jaw Crusher. Our Essa JC1250 Jaw Crusher is small but strong. We modelled it off the tried and tested larger JC2501 after extensive research and

How to effectively reduce the Dust Pollution of Jaw Crusher?

Dust collectors are installed separately at the access port at the back of the moving jaw and the discharging opening to control the diffusion of dust by means of dust collector. The collector cover is about 1 meter away

Causes of Dust Generation in Jaw Crusher Production and Dust

2018年12月26日1. In view of the high-pressure wind generated by the high-speed rotation of the crusher, we can do our best to seal the chute behind the crusher and the belt

Analysis of Dust Generation and Removal Methods in Jaw Crusher

2022年3月22日The dust collecting measure of jaw crusher in the early stage mainly includes two types--spray and dust collecting, and the relevant dust-proof devices are

Dust Collection and Control in Crusher Plant 911

2019年5月14日Dust collection in the crushing plant is accomplished by two wet dust collectors with a total of 66,000 CFM. The dust collectors exhaust air is discharged to the upper ventilation system of the mine

Dust Mitigation in Geochemical Sample Preparation Facilities

Our solution to dust control is to have a box to enclose the jaw crusher and disk mill. This box is connected to a Torit dust collection/filtration unit (see Donaldsontorit).

Crusher dust collection dustdischarge

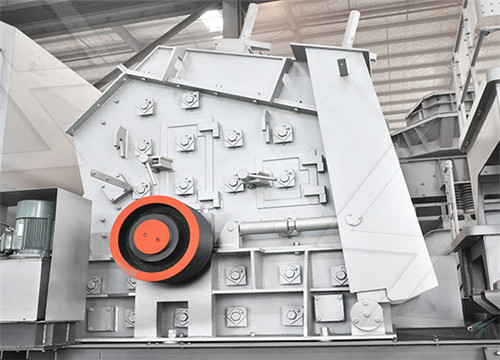

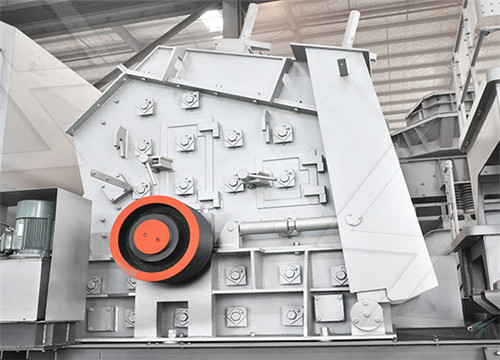

The crusher dust collector is mainly used for the dust removal of jaw crusher, impact crusher, hammer crusher, impact crusher, compound crusher and cone crusher. Working

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the

Jaw Crusher an overview ScienceDirect Topics

1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4.

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe...

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the

Fine Jaw Crushers

Essa® JC1250 Jaw Crusher. Our Essa JC1250 Jaw Crusher is small but strong. We modelled it off the tried and tested larger JC2501 after extensive research and development. For a compact crusher, our JC1250 can handle a high workload up to 5 kg samples comfortably. It has impressive throughput up to 140 kg/hr.

5 Common Questions about Jaw Crushers Answered

2019年5月30日Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as

Improved dust capture methods for crushing plant

2007年2月1日Fig. 2. Ventilation network data for crushing chamber. Dust liberated during sub-surface ore conveyance and loading operations produces a pollutant load to the ventilation system. Primary crusher facilities often employ water sprays, mounted around the perimeter of the crusher feed bin, to suppress dust dispersion.

Causes of Dust Generation in Jaw Crusher Production and Dust

2018年12月26日1. In view of the high-pressure wind generated by the high-speed rotation of the crusher, we can do our best to seal the chute behind the crusher and the belt conveyor. For the high-pressure...

CNA Dust collection method for mine jaw crusher

The invention discloses a dust collection method for a mine jaw crusher and a device thereof. A high-pressure atomization nozzle is arranged at a mine inlet in the top of the jaw crusher and is connected with the water outlet end of a high-pressure plunger pump through a high-pressure pipeline; a pressure sensor and an overflow valve are arranged at the

1.2. Jaw Crusher — CSUN Rock Lab Manual 0.1 documentation

1. Overview of the Zircon Separation Process ? 1.2. Jaw Crusher Edit on GitHub 1.2. Jaw Crusher Note It is recommended to complete preliminary cleaning and set up for both the jaw crusher and the disc mill, then run your sample through both, in that order. Table of contents Jaw Crusher Video tutorial Set Up Processing Your Sample 1.2.1.

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the

Jaw Crusher BB 250 RETSCH

Download The Jaw Crusher BB 250 is specifically designed for accepting large feed sizes up to 120 x 90 mm. The gap width can be set stepless from 0-30 mm. Depending on the sample material, particle sizes down to 2

Jaw Crusher BB 300 RETSCH efficiency and long service life

Download. The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing ratio of 26. A throughput of up to 600 kg/h is possible with the BB 300.

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe...

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日 The plate warping reduces the crusher performance, resulting in low crusher efficiency, high cost of replacing the crushing plates, and higher energy consumption. Moreover, the wear of the...

5 Common Questions about Jaw Crushers Answered

2019年5月30日The exact crushers you need—jaw, cone, impact or gyratory—depend on the jobsite, the product you’re making, and how much you need to produce. An individual crusher’s construction and...

CNA Dust collection method for mine jaw crusher

The invention discloses a dust collection method for a mine jaw crusher and a device thereof. A high-pressure atomization nozzle is arranged at a mine inlet in the top of the jaw crusher and is connected with the water outlet end of a high-pressure plunger pump through a high-pressure pipeline; a pressure sensor and an overflow valve are arranged at the

Jaw crushr operate manual: how to install, repair and examine it

2022年9月30日Installation points of the movable jaw. Assemble the movable jaw parts in advance. After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc. on the ground, use a crane or crane to hoist the assembled parts together on the crusher. In the rack. For sliding bearings, it is necessary to grind and match between the

Jaw crusher JC 15 VIBROTECHNIK

JC 15 is a jaw crusher with a complex movement of the jaw, In the lower part of the housing there is a nozzle for connecting the crusher to the dust collection system. JC 15 Jaw crusher and Cyclone dust collector

Causes Of Dust From Jaw Crusher

2020年3月3日What is the reason for the dust produced by the jaw crusher? 1. Analysis of dust point of jaw crusher: The dust source of jaw crusher mainly comes from the supply port, discharge port and conveying system. The material to be processed is squeezed and crushed by the crusher, and then conveyed to the next step by the conveyor.

HSE Quarries Safe operation and use of mobile jaw

The quarry health and safety document. Useful links. Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition

Fine Jaw Crushers

Essa® JC1250 Jaw Crusher. Our Essa JC1250 Jaw Crusher is small but strong. We modelled it off the tried and tested larger JC2501 after extensive research and

How to effectively reduce the Dust Pollution of Jaw Crusher?

Dust collectors are installed separately at the access port at the back of the moving jaw and the discharging opening to control the diffusion of dust by means of dust collector. The collector cover is about 1 meter away

Causes of Dust Generation in Jaw Crusher Production and Dust

2018年12月26日1. In view of the high-pressure wind generated by the high-speed rotation of the crusher, we can do our best to seal the chute behind the crusher and the belt

Analysis of Dust Generation and Removal Methods in Jaw Crusher

2022年3月22日The dust collecting measure of jaw crusher in the early stage mainly includes two types--spray and dust collecting, and the relevant dust-proof devices are

Dust Collection and Control in Crusher Plant 911

2019年5月14日Dust collection in the crushing plant is accomplished by two wet dust collectors with a total of 66,000 CFM. The dust collectors exhaust air is discharged to the upper ventilation system of the mine

Dust Mitigation in Geochemical Sample Preparation Facilities

Our solution to dust control is to have a box to enclose the jaw crusher and disk mill. This box is connected to a Torit dust collection/filtration unit (see Donaldsontorit).

Crusher dust collection dustdischarge

The crusher dust collector is mainly used for the dust removal of jaw crusher, impact crusher, hammer crusher, impact crusher, compound crusher and cone crusher. Working

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the

Jaw Crusher an overview ScienceDirect Topics

1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4.

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe...

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the

Fine Jaw Crushers

Essa® JC1250 Jaw Crusher. Our Essa JC1250 Jaw Crusher is small but strong. We modelled it off the tried and tested larger JC2501 after extensive research and development. For a compact crusher, our JC1250 can handle a high workload up to 5 kg samples comfortably. It has impressive throughput up to 140 kg/hr.

5 Common Questions about Jaw Crushers Answered

2019年5月30日Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as

Improved dust capture methods for crushing plant

2007年2月1日Fig. 2. Ventilation network data for crushing chamber. Dust liberated during sub-surface ore conveyance and loading operations produces a pollutant load to the ventilation system. Primary crusher facilities often employ water sprays, mounted around the perimeter of the crusher feed bin, to suppress dust dispersion.

Causes of Dust Generation in Jaw Crusher Production and Dust

2018年12月26日1. In view of the high-pressure wind generated by the high-speed rotation of the crusher, we can do our best to seal the chute behind the crusher and the belt conveyor. For the high-pressure...

CNA Dust collection method for mine jaw crusher

The invention discloses a dust collection method for a mine jaw crusher and a device thereof. A high-pressure atomization nozzle is arranged at a mine inlet in the top of the jaw crusher and is connected with the water outlet end of a high-pressure plunger pump through a high-pressure pipeline; a pressure sensor and an overflow valve are arranged at the

1.2. Jaw Crusher — CSUN Rock Lab Manual 0.1 documentation

1. Overview of the Zircon Separation Process ? 1.2. Jaw Crusher Edit on GitHub 1.2. Jaw Crusher Note It is recommended to complete preliminary cleaning and set up for both the jaw crusher and the disc mill, then run your sample through both, in that order. Table of contents Jaw Crusher Video tutorial Set Up Processing Your Sample 1.2.1.

Laboratory and pilot plant Primary Jaw Crushers

Essa JC1000 Jaw Crusher . The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of applications. Known in the

Jaw Crusher BB 250 RETSCH

Download The Jaw Crusher BB 250 is specifically designed for accepting large feed sizes up to 120 x 90 mm. The gap width can be set stepless from 0-30 mm. Depending on the sample material, particle sizes down to 2

Jaw Crusher BB 300 RETSCH efficiency and long service life

Download. The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing ratio of 26. A throughput of up to 600 kg/h is possible with the BB 300.

HSE Quarries Safe operation and use of mobile jaw crushers

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe...

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日 The plate warping reduces the crusher performance, resulting in low crusher efficiency, high cost of replacing the crushing plates, and higher energy consumption. Moreover, the wear of the...

5 Common Questions about Jaw Crushers Answered

2019年5月30日The exact crushers you need—jaw, cone, impact or gyratory—depend on the jobsite, the product you’re making, and how much you need to produce. An individual crusher’s construction and...

CNA Dust collection method for mine jaw crusher

The invention discloses a dust collection method for a mine jaw crusher and a device thereof. A high-pressure atomization nozzle is arranged at a mine inlet in the top of the jaw crusher and is connected with the water outlet end of a high-pressure plunger pump through a high-pressure pipeline; a pressure sensor and an overflow valve are arranged at the

Jaw crushr operate manual: how to install, repair and examine it

2022年9月30日Installation points of the movable jaw. Assemble the movable jaw parts in advance. After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc. on the ground, use a crane or crane to hoist the assembled parts together on the crusher. In the rack. For sliding bearings, it is necessary to grind and match between the

Jaw crusher JC 15 VIBROTECHNIK

JC 15 is a jaw crusher with a complex movement of the jaw, In the lower part of the housing there is a nozzle for connecting the crusher to the dust collection system. JC 15 Jaw crusher and Cyclone dust collector

Causes Of Dust From Jaw Crusher

2020年3月3日What is the reason for the dust produced by the jaw crusher? 1. Analysis of dust point of jaw crusher: The dust source of jaw crusher mainly comes from the supply port, discharge port and conveying system. The material to be processed is squeezed and crushed by the crusher, and then conveyed to the next step by the conveyor.

altage سحق الحجر ilndustries ج مومباي

سعر المصنع مصنع المهني مصنع الانحلال الحراري المطاطي في فنزويلا

الحجر الجيري التي استخدمت مطحنة في الصين

تهتز مورد غربال في الجزائر

تجهیزات ساخت و ساز فهرست

جرار قدرة الانطلاق بالطاقة كسارة الصخور

محطة غسيل الفحم المتنقلة

مطحنة الكرة الخزفية الجزائر

آسیاب چکشی با موتور دیزلی

كساره بركار

الصين محطم القص

خط انتاج تشيزكيك

حصى الحجر البورتلاندي

سعر الدولوميت السعودي

الآلات الصينية المسابك مخروط سحق المعدات

سيور ناقلة مستعملة للبيع في سري لانكا

آلة غربلة الفحم للبيع في الهند

سعر آلة قطع أخيلي للرخام

قوالب الجص باريس للشراء

بيع معدات معالجة الذهب على نطاق صغير

فحص المصنعة في الهند للبيع

مطحنة طحن رمل السيليكا عالية الكفاءة

الفروسية البناء الوظيفي

definisi الاهلى طواحين رايت حساب

كسارة خرسانة عمان

الصين مطحنة وسائل الإعلام وكيل

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20