الحار منتجات

ملكنا الإخبارية

Construction What equipment is required for the grinding station

1926.303 Occupational Safety and Health Administration

1926.303 (c) (3) Cup type wheels used for external grinding shall be protected by either a revolving cup guard or a band type guard in accordance with the provisions of the American National Standards Institute, B7.1-1970 Safety Code for the Use, Care, and Protection of

Angle Grinder Safety Occupational Safety and Health

Angle grinders, also called side or disc grinders, are a handheld power tool used for cutting, grinding and polishing. They can be electric, gas powered, or pneumatic and come in a

Grinding Equipment an overview ScienceDirect Topics

Grinding equipment includes: a storage hopper for the bulk solid to be processed; a feed system using a screw conveyor, a conveyor belt or a vibrating conveyor; a

cement grinding station CHAENG

The whole system of cement grinding station mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is

Safety checklist for working with grinders Atlas Copco

2021年7月23日Use personal protective clothing or other safety equipment provided like goggles, ear protectors, gloves, helmets, , etc. Test run in a safe enclosed area,

Construction Equipment Types And Construction

2021年2月7日Construction Equipment Types. Kindly check the classification of construction equipment and construction equipment names and pictures. Various

New Features of Cement Grinding Station Design

2022年1月12日The building of a cement grinding station does not need high investment and is low-tech, it is easier to popularize. Under the trend of rapid development of

Cement Grinding Plant Expert Cement Grinding

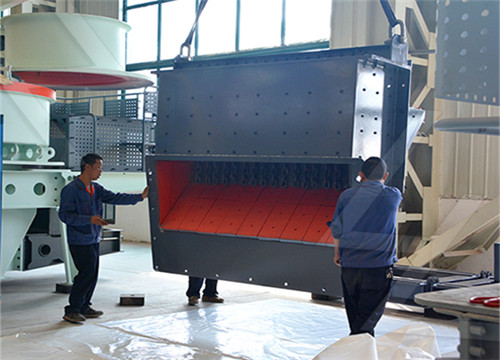

Cement Grinding Equipment. The core equipment in a grinding plant is the cement mill. According to different grinding systems, the often-used cement mills include ball mill,

Cement Grinding Unit Cement Grinding Plant Cement Grinding

There are three common types of processing for cement grinding stations: open-circuit grinding system, closed-circuit grinding system, and combined grinding system. At

Angle grinder self-assessment tool WorkSafe.qld.gov.au

During cutting or grinding activity: Check the work piece is secure and supported. Check the work will be done with sparks travelling away from you. Check the work will not be

Cement mill Wikipedia

Cement mill. A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of size reducer; further granularization

Machine tool Basic machine tools Britannica

Hundreds of varieties of metal machine tools, ranging in size from small machines mounted on workbenches to huge production machines weighing several hundred tons, are used in modern industry. They retain the basic characteristics of their 19th- and early 20th-century ancestors and are still classed as one of the following: (1) turning machines (lathes and

CBMI Construction Co., Ltd

At the same time, the simple and practical design of process and equipment arrangement guarantees the simpleness and convenience of production operation and maintenance. The MMG (ModularMobile Grinding) plant developed by CBMI construction co., LTD, is abiding by the "pre-assembly, modularity and movable" technical route and the concept

Welding, Cutting, and Brazing Standards Occupational Safety

Welding, cutting, and brazing is addressed in specific OSHA standards for general industry, maritime, and construction. This section highlights OSHA standards and documents related to welding, cutting, and brazing. OSHA Standards State Plan Standards

cement grinding station CHAENG

The whole system of cement grinding station mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement mill, OSEPA high-efficiency separator, elevator, packing machine and so on. In order to meet the customers' requirements on different granularity of auxiliary

A Lesson in Angle Grinder Safety AISC

To safeguard against injuries, personal protective equipment (PPE) must be worn by the operator and those around him/her when angle grinding is being performed. devices should be turned off or removed from the area where angle grinding is being performed. Furthermore, operators must make sure they are physically capable of working an angle

Project Management for Construction: Labor, Material and Equipment

The selection of the appropriate type and size of construction equipment often affects the required amount of time and effort and thus the job-site productivity of a project. It is therefore important for site managers and construction planners to be familiar with the characteristics of the major types of equipment most commonly used in construction.

New Features of Cement Grinding Station Design

2022年1月12日The building of a cement grinding station does not need high investment and is low-tech, it is easier to popularize. Under the trend of rapid development of cement grinding station, more new technologies are adopted in its design and construction, and many new features are shown in the following aspects: The location of the cement

A General Overview of a Good Workshop Layout

2023年6月10日Planning a workshop layout starts with making a complete list of the machinery and equipment, allied equipment (such as; dust collector, workshop heating or cooling equipment, exhaust fans, amenities like granite machine, drinking water, power equipment, and equipment to meet the safety and health standard set by local

Cement mill Wikipedia

Cement mill. A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of size reducer; further granularization

Back to Basics Hammer Milling and Jet Milling Fundamentals

mill equipment size, but also dictates how to operate the mill, whether continuous or batch operation is required, and whether the process can be performed in-house or if a tolling service is a better option. The required product size is an important grinding cost factor, especially for fine-size grinding. You should evaluate

Grinding machine Wikipedia

A grinding machine, often shortened to grinder, is a power tool (or machine tool) used for grinding.It is a type of machining using an abrasive wheel as the cutting tool.Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (e.g., low

Machine tool Basic machine tools Britannica

Hundreds of varieties of metal machine tools, ranging in size from small machines mounted on workbenches to huge production machines weighing several hundred tons, are used in modern industry. They retain the basic characteristics of their 19th- and early 20th-century ancestors and are still classed as one of the following: (1) turning machines (lathes and

cement grinding station CHAENG

complete equipment and accessories for cement grinding station; EPC services: complete solutions including design, research and development, manufacturing, transportation, installation, commissioning, training, and after-sales. Suggestions on Scheme Selection CHAENG can provide the complete solutions of 15-100t/h cement grinding station for you.

CBMI Construction Co., Ltd

At the same time, the simple and practical design of process and equipment arrangement guarantees the simpleness and convenience of production operation and maintenance. The MMG (ModularMobile Grinding) plant developed by CBMI construction co., LTD, is abiding by the "pre-assembly, modularity and movable" technical route and the concept

Welding, Cutting, and Brazing Standards Occupational Safety

Welding, cutting, and brazing is addressed in specific OSHA standards for general industry, maritime, and construction. This section highlights OSHA standards and documents related to welding, cutting, and brazing. OSHA Standards State Plan Standards

CEMENGAL: ENGINEERING, EQUIPMENT AND ASSEMBLY FOR

CEMENGAL does the erection of any machinery required for grinding circuits.. Local companies hired by CEMENGAL do the erection under the supervision of our technical experts. The task ends with the start-up of the new plant and verification of the process in each production line.

Project Management for Construction: Labor, Material and Equipment

The selection of the appropriate type and size of construction equipment often affects the required amount of time and effort and thus the job-site productivity of a project. It is therefore important for site managers and construction planners to be familiar with the characteristics of the major types of equipment most commonly used in construction.

تعدين خام النحاس

تحمل التسامح في تبديل واحد كسارة الفك

موردو معدات التكسير في السعودية

التفتيش احتياطي معدات الفك الفك

تصميم تصميم محطة تكسير الخرسانة المتنقلة

انخفاض اهتزاز الصابون حجر مطحنة حجر مطحنة الصابون في الهندية

نتيجة الكسارة الثانوية

أدوات تستخدم ل Concret Brusting وسحق 2

معدات صنع الرمل الناعم ذات الكفاءة العالية لمسحوق تكسير الصخور

100 tph nawa الهندسة كسارة الحجر للبيع

آلة لمناجم الذهب

كسارة الحجر المحمولة في أوروبا

فاصل هيدروغناطيسي كسارة خام الذهب

تستخدم الموردين الحزام الناقل

معدات معالجة الذهب في كولورادو سبرينغز كولورادو الولايات المتحدة

رمل السيليكا محطة الفرز

المعادن شركة تعدين الذهب cl

شراء مناجم الفحم الفحم مناجم الفحم للبيع الأزرق

gold mining rock crusher process for small scale miner

أنواع كسارات الحجر المستخدمة في الأردن

كسارة مخروطية تكسير قياسية

الحصى مجمع طحن مطحنة بتصنيع المورد

كسارات الحجارة المستخدمة من ألمانيا

وعيسى مطحنة

مطاحن الكرة namedtubular manufacturingpany

design calculation for coal chain drag conveyor

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20