الحار منتجات

ملكنا الإخبارية

tube mill bearing cooling water flow chart

Study on cooling process of copper tube after three-roll

2020年1月1日Establishment of finite element model. 2.1. Operating principle and features of cooling process of copper tube after three-roll planetary rolling. Fig. 1 a and b are the

The Cooling Water Handbook Buckman

Common cooling water issues Cooling water has many enemies. Sometimes they work alone. In other instances, they team up and compound the problem. For example, algae

DESIGNING A PROCESS LINE Dairy Processing Handbook

Plate heat exchanger for heating and cooling, a holding tube and a hot water unit. Centrifugal clarifier (as only whole milk is to be treated, a centrifugal separator is not

Water-lubricated stern tube bearing ScienceDirect

2021年1月1日Water axial flow supports lubrication and intensifies bearing cooling. According to bearing manufacturers’ recommendations, the minimum axial water flow

Best coolant practices make perfect The Fabricator

2015年5月28日Many tube mill coolants are just 5 percent to 7 percent metalworking coolant and 93 percent to 97 percent water. That means that a 1,000-gal. system

Manufacturing Processes and Products of Steel Pipes and Tubes in

diameter mill produces pipes and tubes with outer diameters up to 177.8 mm (5”), while the medium-Fig. 1 Manufacturing procedure of pipes and tubes in JFE Steel Kind Works

Proper Tube Mill Coolant

11 SELECTION OF TUBE MILL COOLANT 1. EVALUATE WATER SOURCEEVALUATE WATER SOURCE 93 93 –– 95% of Your Coolant is Water95% of Your Coolant is Water

Examining tube mill roll tooling, setup, and maintenance

2001年9月17日3. Length minimum and maximum. 4. Notching or secondary operations. 5. Reference to mating parts. 6. Attention to critical areas. If a worn-out sample roll is

tube mill bearing cooling water flow chart

2017-8-1 Cold water- for mill bearing cooling (30 m 3 /hr), shredder bearing cooling (20 m 3 /hr) and mill gearing cooling (76 m 3 /hr). Hot water- requires for mill imbibition

Study on cooling process of copper tube after three-roll planetary

2020年1月1日YaoXiaoa Xin-LiangGaoa Yu-QianZhaoc https://doi/10.1016/j.icheatmasstransfer.2019.104393 Get rights and content Highlights • Realize the whole process of three-roll planetary rolling and cooling of the tube. • Simulation method of “stepwise” moving cooling water jacket was used. • •

Manufacturing Processes and Products of Steel Pipes and Tubes

diameter mill produces pipes and tubes with outer diameters up to 177.8 mm (5”), while the medium-Fig. 1 Manufacturing procedure of pipes and tubes in JFE Steel Kind Works Line Available size (mm) Remarks OD Wall thickness Length Seamless pipe Chita Works Small diameter seamless pipe mill 25.4– 177.8 2.3–40.0 22 000 Mannesmann piercing

Tube Maintenance CPI i

Certain liquid cooled tubes are sensitive to the direction of water flow. The direction of water flow may be a function of whether the tube is mounted with its anode up or down. Adequate water flow is critical in water cooled tubes to prevent localized boiling and destruction of the tube. Check the tube dat a sheet for infor mation on direction

Solving problems on the tube mill The Fabricator

2001年8月16日A good maintenance program, as well as rebuilds or upgrades when necessary, is essential. 6. Mill in misalignment. Tube mill misalignment, poor mill condition, and inaccurate setup account for 95 percent of all problems in tube production. Most mills should be aligned at least once a year. 7. Tooling in poor condition.

(PDF) AIR COOLED FIN FAN HEAT EXCHANGER SELECTION

2020年3月31日This is in contrast to rejecting heat to water and then rejecting it to air, as with a shell and tube heat exchanger and a wet cooling tower system. Discover the world's research 25+ million members

DESIGN CALCULATIONS FOR THE COOLING WATER SYSTEM

2017年5月30日 The fresh water cooling system shall use distilled or treated water provided by fresh water generator system on board and is passed through a heat exchanger (shell and tube type),...

Introduction to Rolling Process Cambridge University Press

2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product- flat, sections or hollow sections rolling. (iii) Direction of rolling- lengthwise, transverse, and skew rolling. (iv) Mode of rolling mill operation- continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed. When two rolls of equal diameter and with axis

Oil/Air Lubrication Systems for Steel Production Facilities

No water cooling Water cooled housing Bench test conditions (bearing temperature rise) Test bearing : 22318RHW33 (bore diameter φ90 mm, outer diameter φ190 mm, width 64 mm) Rotating ring: inner ring Radial load : Fr=9.8 kN Lubrication : Oil/air lubrication Oil supply 3 cm3/h Oil type : ISO VG220 Cooling : 1) None 2) Water

tube mill bearing cooling water flow chart

Cooling Water Requirements For Api 610 Pumps. 2009-4-15 API 610 describes the following cooling plans for pumps based on its design for overhung pumps (the most ommon configuration): Plan A: cooling to bearing housing. Plan D: gland quench. Plan K: cooling to bearing housing with parallel flow to seal heat exchanger.

SEAWATER LUBRICATED PROPELLER SHAFT BEARINGS

Thordon Bearings, a pioneer in the development of pollution free bearing designs, offers a variety of choices of seawater lubricated propeller shaft bearing systems for all water conditions. Open, seawater lubricated bearing options include Thordon COMPAC, RiverTough, SXL and XL; each offering specific advantages for different

Study on cooling process of copper tube after three-roll planetary

2020年1月1日YaoXiaoa Xin-LiangGaoa Yu-QianZhaoc https://doi/10.1016/j.icheatmasstransfer.2019.104393 Get rights and content Highlights • Realize the whole process of three-roll planetary rolling and cooling of the tube. • Simulation method of “stepwise” moving cooling water jacket was used. • •

Water Handbook Cooling Water Systems-Heat Transfer Veolia

Monitoring The function of a cooling system is to remove heat from processes or equipment. Heat removed from one medium is transferred to another medium, or process fluid. Most often, the cooling medium is water. However, the heat transfer concepts and calculations discussed in this chapter can also be applied to other fluids.

Manufacturing Processes and Products of Steel Pipes and Tubes

diameter mill produces pipes and tubes with outer diameters up to 177.8 mm (5”), while the medium-Fig. 1 Manufacturing procedure of pipes and tubes in JFE Steel Kind Works Line Available size (mm) Remarks OD Wall thickness Length Seamless pipe Chita Works Small diameter seamless pipe mill 25.4– 177.8 2.3–40.0 22 000 Mannesmann piercing

Solving problems on the tube mill The Fabricator

2001年8月16日A good maintenance program, as well as rebuilds or upgrades when necessary, is essential. 6. Mill in misalignment. Tube mill misalignment, poor mill condition, and inaccurate setup account for 95 percent of all problems in tube production. Most mills should be aligned at least once a year. 7. Tooling in poor condition.

Tube Maintenance CPI i

Adequate water flow is critical in water cooled tubes to prevent localized boiling and destruction of the tube. Check the tube dat a sheet for infor mation on direction of flow and cooling water volume requirements. Vapor cooled tubes require the correct water level be

(PDF) AIR COOLED FIN FAN HEAT EXCHANGER SELECTION

2020年3月31日This is in contrast to rejecting heat to water and then rejecting it to air, as with a shell and tube heat exchanger and a wet cooling tower system. Discover the world's research 25+ million members

Water Flow RateSizing Guide Marlo, Inc

17.1 Total Iron in ppm or mg/l. Total Dissolved Solids (TDS) in ppm or mg/l. pH Determine the daily water usage amount to be softened A. Use consumption figures from water utility billings. (To convert billings in cubic feet to gallons multiply by 7.5) Take water meter readings. Use sizing tables when Steps A or B are not available.

Introduction to Rolling Process Cambridge University Press

2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product- flat, sections or hollow sections rolling. (iii) Direction of rolling- lengthwise, transverse, and skew rolling. (iv) Mode of rolling mill operation- continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed. When two rolls of equal diameter and with axis

Oil/Air Lubrication Systems for Steel Production Facilities

No water cooling Water cooled housing Bench test conditions (bearing temperature rise) Test bearing : 22318RHW33 (bore diameter φ90 mm, outer diameter φ190 mm, width 64 mm) Rotating ring: inner ring Radial load : Fr=9.8 kN Lubrication : Oil/air lubrication Oil supply 3 cm3/h Oil type : ISO VG220 Cooling : 1) None 2) Water

SEAWATER LUBRICATED PROPELLER SHAFT BEARINGS

Thordon Bearings, a pioneer in the development of pollution free bearing designs, offers a variety of choices of seawater lubricated propeller shaft bearing systems for all water conditions. Open, seawater lubricated bearing options include Thordon COMPAC, RiverTough, SXL and XL; each offering specific advantages for different

دراسه مشروع محاجررخام وقرانيت

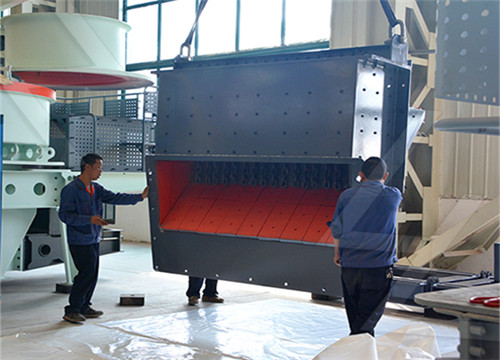

شاشة كبيرة تهتز المختبر

أين تجد خام الفضة

انتعاش الذهب على نطاق صغير وحدات النباتات

تستخدم المعدنية طحن النباتات

مصغرة قصب السكر في الكسارات

آلة طاحونة الزجاج سنغافورة

كسارات الحجر المحمول ايرلندا الشمالية

عجلات مطحنة الكرة الرطبة ذات الصلة

نوعية جيدة

آلة لفصل الرمال والذهب

الفك محطم سعر التاميل نادو

مطاحن الكرة مختبر اليمن

الألغام الجرانيت في نيوزيلندا

فوسفات الصخور المنقولة موبايل الحجر كسارة

توزيع وإنتاج العالم لصناعة الحديد

40 60 Tph كسارة الحجر اقامة التكلفة

قدرة تهتز الشاشات حجم أمبير

خلاط السلبي مع مطحنة

القوى النابذة بال مطحنة

مخطط التجمع كسارة مخروطية

سنگ آهن و سنگ معدن مس در خرد کردن

التفاصيل مطحنة الكرة في المعدات

تطبيقات فعالة من خوارزميات رؤية الجهاز باستخدام

أنواع تعدين الذهب في جنوب إفريقيا

رمال التعدين في سريلانكا

حول لدينا

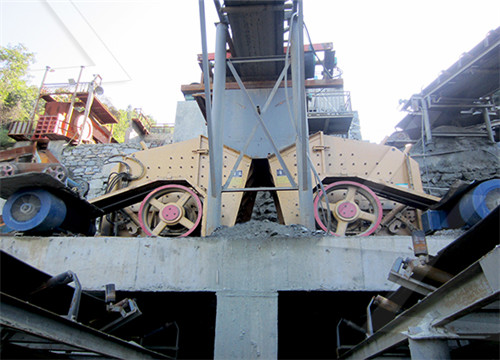

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20