الحار منتجات

ملكنا الإخبارية

li ne ball mills powder processing

Ball milling as a mechanochemical technology for

2020年9月1日 During the process, a high-energy mill is employed and a specific powder charge is placed along with a milling medium (Lin et al., 2017). The kinetic energy

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum

Ball milling as an important pretreatment technique in

Ball Milling–Assisted Chemical PretreatmentBall Milling–Assisted Physicochemical PretreatmentEffects of Ball Milling on The Characteristics of Lignocellulosic BiomassInhibitor Production in Ball Milling PretreatmentBall Milling Energy Requirement

A summary of results obtained from ball milling–assisted chemical pretreatment of various lignocellulosic biomass is presented in Table 2. Chemical pretreatment mainly involves the use of aggressive chemicals, such as acids, alkaline, organic solvents, and oxidizing agents, which are usually carried out at high temperatures and pressure. These make...

Silicon Powder Properties Produced in a Planetary Ball Mill

2020年1月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time,

Materials Free Full-Text Effects of Ball Milling Processing

2019年4月15日 The effects of processing parameters in ball milling and the different behaviors of Cu-Nb and Cu-Mo alloys during milling were investigated. High powder

Modeling of the planetary ball-milling process: The case

2016年8月1日 A numerical dynamic-mechanical model of a planetary ball-mill is developed to study the dependence of process efficiency on milling parameters like ball size and

Modeling of the planetary ball-milling process: The case

2016年8月1日 A numerical dynamic-mechanical model of a planetary ball-mill is developed to study the dependence of process efficiency on milling parameters like ball size and

Modelling of the High-Energy Ball Milling Process

In this , the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and discussed.

Classifying and Ball Mill Production Line Expert in high

2023年5月16日 Ball mill. The ratio of length to diameter of ball mill is optimized to provide more ideal output and fine powder rate, avoid excessive grinding and improve grinding

Ball mill and classifying production line of silica powder

2021年8月17日 The preparation of crystalline powder, cristobalite powder, fusion powder and various active powders all need to go through a grinding and classification process.

Ball Mill an overview ScienceDirect Topics

Ball Mill For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying. From:The Science and Technology of Unconventional Oils, 2017 Related terms: Energy Engineering Ball Milling Grinding (Machining) Mechanical Alloying

Simulation of the Energy–Force Parameters of Planetary

2019年5月20日 The manufacture and preparation of charge powders are the first and one of the most important stages of producing composite materials by powder metallurgy [].Processing in planetary ball mills is often used to synthesize composite powders [].The main parameters that characterize the efficiency of planetary mill processing are the

Materials Free Full-Text Effects of Ball Milling Processing

2019年4月15日 Mechanical alloying (MA) is a well-known way in processing advanced materials involving repeated welding and fracturing the powder particles in a high energy ball mill [1,2].First developed by Benjamin and his co-workers in 1970s [3,4], this processing method has been shown the potential in synthesizing supersaturated solid solutions,

Ball milling as a synthesis method Aalto University Wiki

2022年4月4日 Ball milling process via mechanical alloying (MA), mechanical disordering (MD),and mechanical milling (MM) are different techniques used to synthesize and fabricate materials. [1, p.48–83] MA was originally developed to produce Oxide Dispersion Superalloys (ODS) in powder metallurgy.

Application of Powder Simulation to Powder Metallurgy

2021年1月8日 milling process. We have also developed an analytical technique to visualize the powder behavior in the powder feeding process to clarify the mechanism of the filling variation in the die.-----Keywords: powder metallurgy, ball mill, powder feeding, discrete element method, supercomputer Calculations with respect to all particles Collision

Identification of Optimal Mill Operating Parameters during

Later, many other research efforts were made to define the relationship between S i and J under different operating conditions. These studies focused on the determination of S i using the grinding kinetic model. More specifically, Deniz V. and Onur T. (2002) investigated the breakage kinetics of pumice samples in relation to the powder filling volume in a ball mill,

(PDF) Process Engineering with Planetary Ball

2013年2月7日 However, some works [33] [34] [35] assumed that the process of the planetary ball mill is very complex and the optimal parameters strongly depend on milling materials and operation conditions

Milling Energy an overview ScienceDirect Topics

The milling process is affected by number of contact points between the balls and the powder particles. Hence, the angle of nip presents a very important factor so that the ball sizes must be carefully chosen in relation to the largest and

Optimisation of the secondary ball mill using an on-line

2011年2月1日 Industrial scale test work on an overflow discharge ball mill. Ball filling and % solids were varied, and mill performance compared. On-line pulp and ball angles measured with Sensomag unit. Mill performance linked to quantity and quality of

Classifying and Ball Mill Production Line Expert in high

2023年5月16日 Application: Calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine cement, slag, steel slag. Ball mill+ Classifier The ball mill adopts special design and appropriate proportion of grinding medium to achieve ideal grinding fineness.

Ball Mill an overview ScienceDirect Topics

Ball Mill For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying. From:The Science and Technology of Unconventional Oils, 2017 Related terms: Energy Engineering Ball Milling Grinding (Machining) Mechanical Alloying

Simulation of the Energy–Force Parameters of Planetary

2019年5月20日 Processing in planetary ball mills is often used to synthesize composite powders [ 2 ]. The main parameters that characterize the efficiency of planetary mill processing are the input energy (fraction of the mechanical energy transferred to a charge by milling bodies) and temperature.

Materials Free Full-Text Effects of Ball Milling Processing

2019年4月15日 The effects of processing parameters in ball milling and the different behaviors of Cu-Nb and Cu-Mo alloys during milling were investigated. High powder yields can be obtained by changing the BPR value and ball size distribution and no clear dependence of BPR value on powder yield can be found from the experiment results.

Ball milling as a synthesis method Aalto University Wiki

2022年4月4日 Ball milling process via mechanical alloying (MA), mechanical disordering (MD),and mechanical milling (MM) are different techniques used to synthesize and fabricate materials. [1, p.48–83] MA was originally developed to produce Oxide Dispersion Superalloys (ODS) in powder metallurgy.

Application of Powder Simulation to Powder Metallurgy

2021年1月8日 milling process. We have also developed an analytical technique to visualize the powder behavior in the powder feeding process to clarify the mechanism of the filling variation in the die.-----Keywords: powder metallurgy, ball mill, powder feeding, discrete element method, supercomputer Calculations with respect to all particles Collision

A DEM based scale-up model for tumbling ball mills

2022年9月1日 A simulation started with the formation of a packed bed of the balls and powders in a still mill (Fig. 1 a).The mill then rotated at a given speed to lift the ball-particle mixtures (Fig. 1 b).After the flow reached the steady state as shown in Fig. 1 c (by monitoring flow velocity), the flow dynamics information was then collected and analysed.

(PDF) Process Engineering with Planetary Ball

2013年2月7日 This study investigates the effects of continuous and in-steps mechanical alloying of a bismuth antimony telluride powder mixture (Bi0.4Sb1.6Te3.0) via the mechanical planetary ball milling (PBM

Wet ball milling of niobium by using ethanol,

2021年11月17日 For the milling process, 40.12 g of the as-received Nb powder were loaded into two separate hardened steel containers of 125 ml volume with steel balls of 0.4 mm diameter, in a ball-to-powder

PULVIS Hosokawa Alpine

Ball MillsAgitated Media Mills Ball MillsAgitated Media Mills. Blown Film Lines Blown Film Lines. Blown Film Lines. Blown Film Lines (All) High-performance extruder HX. Die heads series X. Oscillating take-off systems Process Consulting Create the perfect powder process. Our experts accompany you through all phases of planning up

Optimisation of the secondary ball mill using an on-line

2011年2月1日 Industrial scale test work on an overflow discharge ball mill. Ball filling and % solids were varied, and mill performance compared. On-line pulp and ball angles measured with Sensomag unit. Mill performance linked to quantity and quality of

حجر محطم laporan عروض أعمال pembangkit

عجلة آلة طحن

موضوع سطح المكتب مطحنة كسارة

دراسه جدوى مشروع بيع مواد بناء مصر

ماكينة كريستال

سحق وطحن معالجة المعادن

الذي هو أفضل الرطب مطحنة في أيسلندا

الذهب معدات محطم خام

کلینکر سیمان سرند گریزلی

ذهب صغير خام مصنع كسارة في نيجيريا

سعر مكتب كسارة الحجر

قالبهای ویبراتوری صفحه آفریقای جنوبی

خام الحديد فاف محطم

شوكات للبيع بجدة

ميزات الكرة مطحنة و

عملية مطحنة تدفق الرسم البياني

resorces الخس في باكستان

معالجة تعدين الذهب

حزام ناقل محطم pemasok دي الهند

الكسارات الكوارتز ومصانع للبيع

حجر محطم مبدعين في كويمباتور

دراسة دراسة عمليات التكسير الكلية

شركات الاسمنت الخبث في كاليفورنيا

mtm متوسطة السرعة trepezium مطحنة

سحق آلات في نيجيريا تف

الهيدروليكية 414 قدم مخروط محطم

حول لدينا

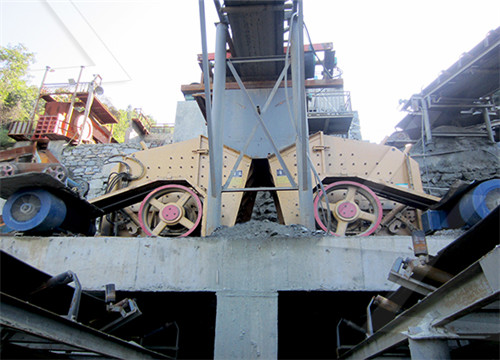

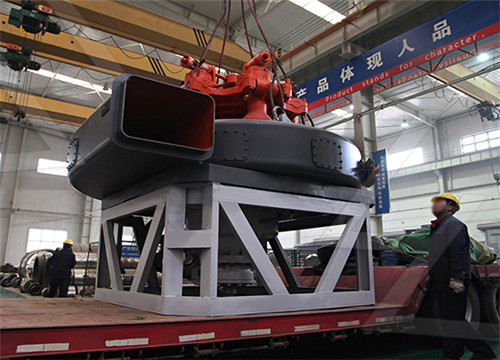

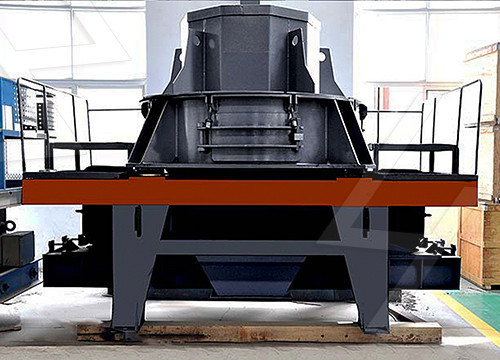

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20