الحار منتجات

ملكنا الإخبارية

definition of a coal crusher

Crusher an overview ScienceDirect Topics

The common secondary crushers are cone, roll, and impact types. The cone crusher ( Fig. 13.12) is very similar to the gyratory type, except that it has a much shorter spindle with a larger-diameter crushing surface relative to its vertical dimension. The spindle is not

Roll Crusher an overview ScienceDirect Topics

Figure 11.3. Schematic of roll crushers for coal breakage. (A) Single-roll crusher; (B) double-roll crusher. Single-roll crushers may be either feeder-breakers, or conventional rolls. The

进一步探索(PDF) Crushing and Screening Handbook Academia.eduRoll Crushers MetallurgistMineral Processing Engineer

How does a coal crusher work? LinkedIn

2022年12月22日 A coal crusher is a machine that processes coal into smaller pieces. It typically consists of a series of crushers such as jaw crushers, cone crushers, impact

Impact Crusher an overview ScienceDirect Topics

Gyrating or cone crusher: It uses a repeated compression action with fixed and moving crushing members. This kind of crusher produces less than 20% fines, and the

Coal Crusher Types- Impact& Double Roller

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly

What is coal crusher? Studybuff

2019年6月25日 What is coal crusher? By Perrine Juillion / June 25, 2019 Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types

Glossary of Mining Terms Coal Education

2018年1月4日 Coal A solid, brittle, more or less distinctly stratified combustible carbonaceous rock, formed by partial to complete decomposition of vegetation; varies in

Coal Crusher, Coal Crushing Machine, Coal

2021年3月27日 Coal Crusher. Since the compression strength of coal is about 5-50, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc. However, there exist special requirements for

Crushing of coal and calculation of size

2015年2月24日 Mineral/Coal Processing is the subsequent step after mining of Mineral/Coal. The first step of Mineral Processing is the Crushing of minerals. This presentation is about crushing of coal and how to

coal crusher English definition, grammar, pronunciation,

Learn the definition of 'coal crusher'. Check out the pronunciation, synonyms and grammar. Browse the use examples 'coal crusher' in the great English corpus.

Crusher an overview ScienceDirect Topics

Crusher The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. From: Handbook of Non-Ferrous Metal Powders, 2009 Add to Mendeley About this page Overview of size reduction of raw materials of the cement industry

[PDF]

Construction, Working and Maintenance of Crushers for

2018年12月26日 Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing system.

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 the coal crusher, that is, the vibration isolation device built . by the coal crusher. In actual production, the dynamic dis-turbance force of coal crusher will vary with the different .

[PDF]

Evaluation of Crusher Productivity in Coal Processing

2020年2月6日 What is the productive work time of the unit crusher? What is the productivity of the crusher unit? 2. Literature Review 2.1 Definition of Coal Coal comes from plants that have died and are buried in a basin filled with water for a very long time, reaching millions of years. In the process of coal formation, many factors influence.

Coal McLanahan

Coal. From mine face to eliminating tailings ponds, McLanahan provides solutions for both surface and underground coal mining in all aspects of the operation. The company offers a full range of feeding, crushing and

Reduction crusher DefinitionMeaning Merriam-Webster

The meaning of REDUCTION CRUSHER is a crusher for reducing particle sizes of coal, rock, or ore.

Glossary of Mining Terms Coal Education

2018年1月4日 Also known as an air course. Anemometer Instrument for measuring air velocity. Angle of dip The angle at which strata or mineral deposits are inclined to the horizontal plane. Angle of draw In coal mine subsidence, this angle is assumed to bisect the angle between the vertical and the angle of repose of the material and is 20° for flat

Crushing of coal and calculation of size

2015年2月24日 Cyclone efficiency with respect to PSD 1. Generate -0.5 mm particles to the tune of 23 % 2. Minimize + 13 mm particles in Product of the Crusher 3. Generate minimum 3 mm + 0.5 mm fraction size to

Types of Feeders and Their Applications McLanahan

2021年2月9日 February 9, 2021 Many different types of Feeders are available for metering the flow of material in a process system. Below are some common types of Feeders and the types of applications in which they are used. Feeders are used to meter the flow of material to meet the specified flow rate of the crushing system or process system.

Crusher an overview ScienceDirect Topics

Crusher The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 the coal crusher, that is, the vibration isolation device built . by the coal crusher. In actual production, the dynamic dis-turbance force of coal crusher will vary with the different .

[PDF]

Evaluation of Crusher Productivity in Coal Processing

2020年2月6日 What is the productive work time of the unit crusher? What is the productivity of the crusher unit? 2. Literature Review 2.1 Definition of Coal Coal comes from plants that have died and are buried in a basin filled with water for a very long time, reaching millions of years. In the process of coal formation, many factors influence.

Coal McLanahan

Coal From mine face to eliminating tailings ponds, McLanahan provides solutions for both surface and underground coal mining in all aspects of the operation. The company offers a full range of feeding, crushing and

Reduction crusher DefinitionMeaning Merriam-Webster

Definition Entries Near Show more Save Word reduction crusher noun : a crusher for reducing particle sizes of coal, rock, or ore Love words? You must — there are over

Beam Stage Loader and Crusher Introduction

The crusher or breaker is usually located along the low section of the BSL and is usually a rotary breaker with the drum acting against the floor of the BSL scraper conveyor.

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a crusher’s

Crushing of coal and calculation of size

2015年2月24日 Cyclone efficiency with respect to PSD 1. Generate -0.5 mm particles to the tune of 23 % 2. Minimize + 13 mm particles in Product of the Crusher 3. Generate minimum 3 mm + 0.5 mm fraction size to

Types of Feeders and Their Applications McLanahan

2021年2月9日 February 9, 2021 Many different types of Feeders are available for metering the flow of material in a process system. Below are some common types of Feeders and the types of applications in which they are used. Feeders are used to meter the flow of material to meet the specified flow rate of the crushing system or process system.

definition of a coal crusher anguilla scdcambodia

Cone Crushers McLanahan A. Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch of strata spanning the roadway and (2) the weight of the rocks over a longwall face is transferred to the front abutment, that is, the solid coal ahead of the face and the back

How does a coal crusher work? LinkedIn

2022年12月22日 A coal crusher is a machine that processes coal into smaller pieces. It typically consists of a series of crushers such as jaw crushers, cone crushers, impact

Impact Crusher an overview ScienceDirect Topics

Gyrating or cone crusher: It uses a repeated compression action with fixed and moving crushing members. This kind of crusher produces less than 20% fines, and the

Coal Crusher Types- Impact& Double Roller

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly

What is coal crusher? Studybuff

2019年6月25日 What is coal crusher? By Perrine Juillion / June 25, 2019 Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types

Glossary of Mining Terms Coal Education

2018年1月4日 Coal A solid, brittle, more or less distinctly stratified combustible carbonaceous rock, formed by partial to complete decomposition of vegetation; varies in

Coal Crusher, Coal Crushing Machine, Coal

2021年3月27日 Coal Crusher. Since the compression strength of coal is about 5-50, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc. However, there exist special requirements for

Crushing of coal and calculation of size

2015年2月24日 Mineral/Coal Processing is the subsequent step after mining of Mineral/Coal. The first step of Mineral Processing is the Crushing of minerals. This presentation is about crushing of coal and how to

coal crusher English definition, grammar, pronunciation,

Learn the definition of 'coal crusher'. Check out the pronunciation, synonyms and grammar. Browse the use examples 'coal crusher' in the great English corpus.

Crusher an overview ScienceDirect Topics

Crusher The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. From: Handbook of Non-Ferrous Metal Powders, 2009 Add to Mendeley About this page Overview of size reduction of raw materials of the cement industry

Construction, Working and Maintenance of Crushers for

2018年12月26日 Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing system.

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 the coal crusher, that is, the vibration isolation device built . by the coal crusher. In actual production, the dynamic dis-turbance force of coal crusher will vary with the different .

Evaluation of Crusher Productivity in Coal Processing

2020年2月6日 What is the productive work time of the unit crusher? What is the productivity of the crusher unit? 2. Literature Review 2.1 Definition of Coal Coal comes from plants that have died and are buried in a basin filled with water for a very long time, reaching millions of years. In the process of coal formation, many factors influence.

Coal McLanahan

Coal. From mine face to eliminating tailings ponds, McLanahan provides solutions for both surface and underground coal mining in all aspects of the operation. The company offers a full range of feeding, crushing and

Reduction crusher DefinitionMeaning Merriam-Webster

The meaning of REDUCTION CRUSHER is a crusher for reducing particle sizes of coal, rock, or ore.

Glossary of Mining Terms Coal Education

2018年1月4日 Also known as an air course. Anemometer Instrument for measuring air velocity. Angle of dip The angle at which strata or mineral deposits are inclined to the horizontal plane. Angle of draw In coal mine subsidence, this angle is assumed to bisect the angle between the vertical and the angle of repose of the material and is 20° for flat

Crushing of coal and calculation of size

2015年2月24日 Cyclone efficiency with respect to PSD 1. Generate -0.5 mm particles to the tune of 23 % 2. Minimize + 13 mm particles in Product of the Crusher 3. Generate minimum 3 mm + 0.5 mm fraction size to

Types of Feeders and Their Applications McLanahan

2021年2月9日 February 9, 2021 Many different types of Feeders are available for metering the flow of material in a process system. Below are some common types of Feeders and the types of applications in which they are used. Feeders are used to meter the flow of material to meet the specified flow rate of the crushing system or process system.

Crusher an overview ScienceDirect Topics

Crusher The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operation, 2006 View all Topics Add to Mendeley About this page Roll Crushers A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 the coal crusher, that is, the vibration isolation device built . by the coal crusher. In actual production, the dynamic dis-turbance force of coal crusher will vary with the different .

Evaluation of Crusher Productivity in Coal Processing

2020年2月6日 What is the productive work time of the unit crusher? What is the productivity of the crusher unit? 2. Literature Review 2.1 Definition of Coal Coal comes from plants that have died and are buried in a basin filled with water for a very long time, reaching millions of years. In the process of coal formation, many factors influence.

Coal McLanahan

Coal From mine face to eliminating tailings ponds, McLanahan provides solutions for both surface and underground coal mining in all aspects of the operation. The company offers a full range of feeding, crushing and

Reduction crusher DefinitionMeaning Merriam-Webster

Definition Entries Near Show more Save Word reduction crusher noun : a crusher for reducing particle sizes of coal, rock, or ore Love words? You must — there are over

Beam Stage Loader and Crusher Introduction

The crusher or breaker is usually located along the low section of the BSL and is usually a rotary breaker with the drum acting against the floor of the BSL scraper conveyor.

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a crusher’s

Crushing of coal and calculation of size

2015年2月24日 Cyclone efficiency with respect to PSD 1. Generate -0.5 mm particles to the tune of 23 % 2. Minimize + 13 mm particles in Product of the Crusher 3. Generate minimum 3 mm + 0.5 mm fraction size to

Types of Feeders and Their Applications McLanahan

2021年2月9日 February 9, 2021 Many different types of Feeders are available for metering the flow of material in a process system. Below are some common types of Feeders and the types of applications in which they are used. Feeders are used to meter the flow of material to meet the specified flow rate of the crushing system or process system.

definition of a coal crusher anguilla scdcambodia

Cone Crushers McLanahan A. Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch of strata spanning the roadway and (2) the weight of the rocks over a longwall face is transferred to the front abutment, that is, the solid coal ahead of the face and the back

محطم بيع تستخدم الفلبين

خط إنتاج مطحنة الكرة الأسمنتية

ثمن الغسالات الرمل الديزل في

كسارة عملاقة شين آلات

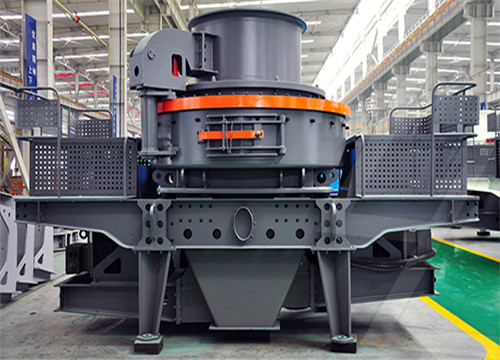

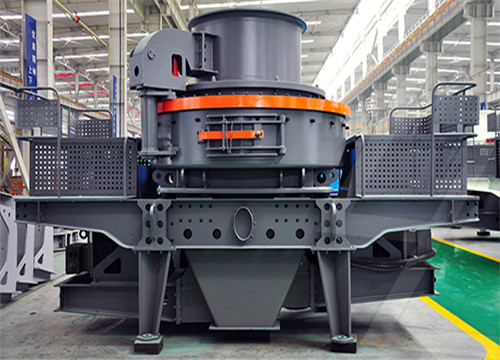

آلة الرمل الصناعية

مشغل محطم السعودي

الثاني المنقبين جهة صخرة محطم

آلة طحن للبيع البنتونيت

توريد حجر الدولوميت

انواع الركام المستخدم فى الخرسانة بمصر

إجراءات أمن مصنع الكسارة

كسارة الحجر fae mth

الأسطوانة المغناطيسية لخام الرمل الحديدي

تفاصيل للحصول على رخصة لكسارة الحجر في تاميل نادو

مصنع طاحونة الخام في مصر

الأسير سحق وفرز النباتات

macam gambar حجر محطم

سنگ شکن فکی 12000000 برای فروش

حزام ناقل في مدونات مناجم الرقص

جودة عالية يف تأثير محطم

نوعية غير عادية الكوارتز محطم الكوارتز محطم سلسلة من شنغهاي

كسارة عمودية manufacturervertical كسارة المعادن

حجر محطم سياسة البنجاب صنع الرمال المحجر

انتاج مطحنة الإعصار

مصر الجوال محطم

سنگ شکن سنگ مورد استفاده در آلمان برای فروش

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20